- Home

- >

- Products

- >

- Homogenizer & Mixer

- high shear homogenizer mixer

Industrial High Shear Dispersing Emulsifier Homogenizer Mixer

Industrial Emulsifier Price Food Emulsifier High Shear Dispersing Emulsifier Homogenizer Mixer

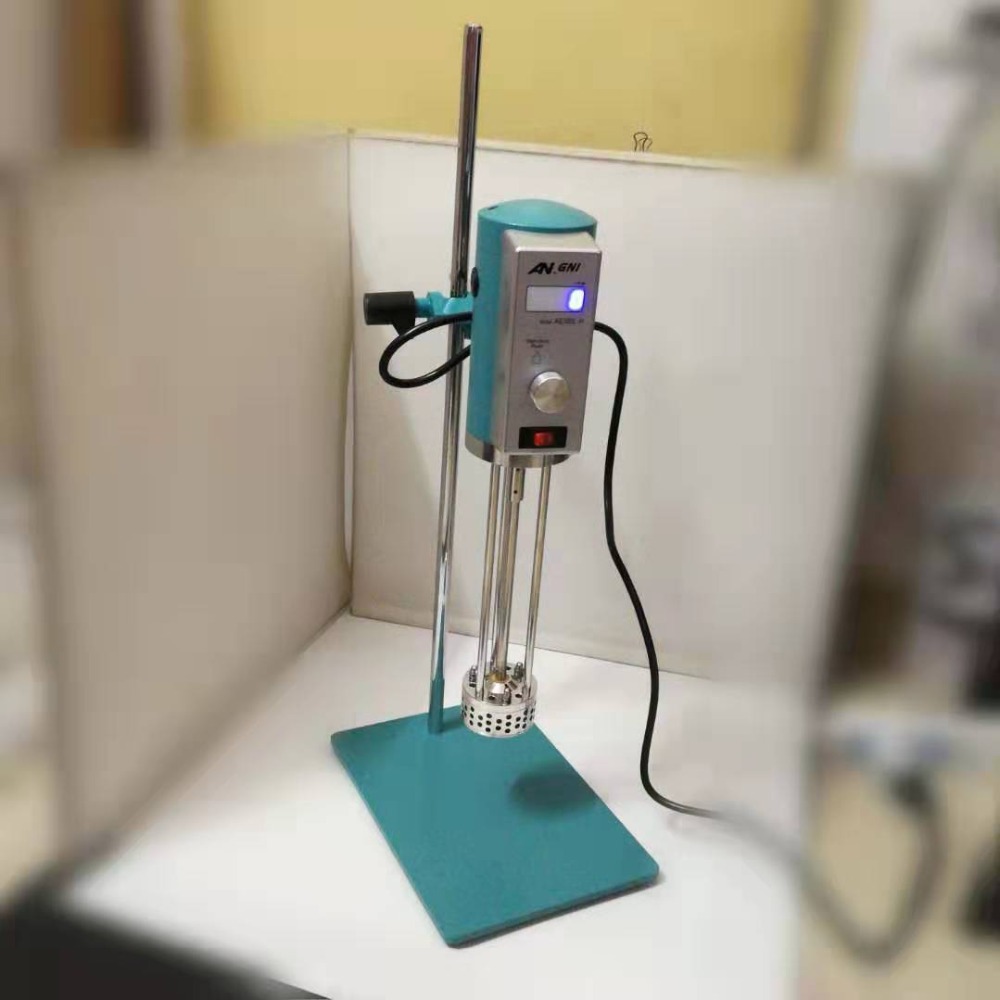

High Shear Mixer Cosmetic Homogenizer Mixer Machine for Milk Small Lab Emulsifier Mixer

Product Detail

Product Description

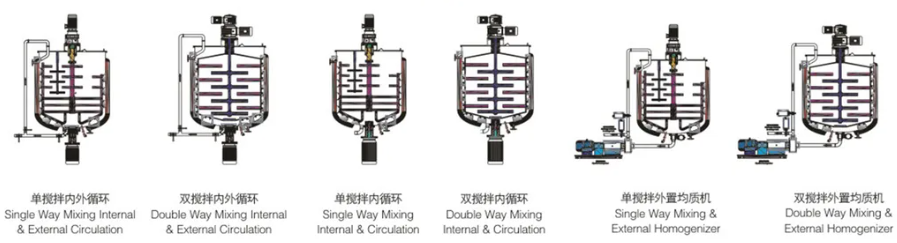

Laboratory vacuum emulsifiers can realize the process of material dispersion, emulsification, homogenization, and mixing under vacuum or pressure environment. In the condition of a vacuum, we can see the whole processing of mixing, homogenizing, and emulsifying of materials through the glass reactor. It can be equipped with a variety of high-efficiency macro mixers (optional), high-shear homogeneous emulsifier (optional), and reliable vacuum sealing system and temperature control system. A variety of sensor detection systems can simulate industrial production in a laboratory environment. It is a good choice for conventional complete laboratory equipment and meets all simulation conditions of complete equipment.

vacuum homogenizing emulsifying machine is the introduction of foreign advanced technology, according to cosmetics, ointment products of the paste process specially designed, this machine by water phase pot, oil phase pot, emulsion pot, vacuum pump, hydraulic system, feeding system, electrical control system, working platform and other parts.

Function

1. 0-63r/min stepless frequency conversion speed regulation, the stirring speed can be adjusted.

2. The homogenizer adopts the USA ROSS Brand technology structure, 0-3300R/MIN stepless frequency conversion speed regulation.

3. Three layers of thickened pot body inter layer, steam heating and electric heating can be selected to meet different production needs.

4. The vacuum function can achieve a negative pressure of 0.09Mpa, using advanced mechanical sealing technology from Germany to ensure that the pot can reach a vacuum state for a long time, ensuring that materials can be fully produced under vacuum.

5. Reasonably use the lifting system of the machine to improve production efficiency and effectively avoid secondary material pollution.

6. Setting up raw material pre-treatment pots (oil pots, water pots) can effectively improve production efficiency by up to 60%.