whta is Vanilla Solvent Extraction equipment ?

2025-11-29

Vanilla Solvent Extraction equipment

The extraction of vanilla requires preserving its complex aromatic components, as traditional methods often lead to the loss of heat-sensitive substances. Modern industrial extraction primarily employs supercritical CO₂ extraction or solvent extraction techniques, which are particularly suitable for the production of high-value-added natural fragrances. These types of equipment are widely used in the food, cosmetics, and pharmaceutical industries, emphasizing residue-free, high-purity, and scalable operations

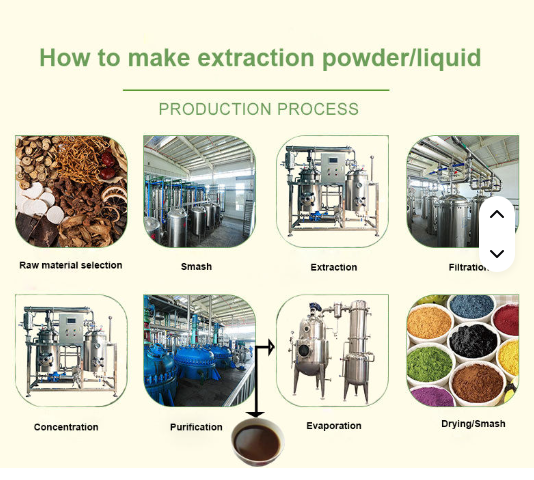

Vanilla Solvent Extraction process

Vanilla Solvent Extraction Raw material selection:

High quality vanilla beans (such as those produced in Madagascar/Indonesia) have a vanillin content of>2%, and B-grade beans (3-4 inches) are suitable for extraction at a lower cost.

Vanilla Solvent Extraction Purity standard: Food grade products must comply with the GB2760-2024 additive specification, with no excessive heavy metals, and organic certified products must have no residual synthetic solvents

Vanilla Solvent Extraction process:Cut the vanilla pods and soak them in ethanol solution (concentration 35% -50%) for several months. Filter the residue, recover the solvent by vacuum distillation, and obtain a thick vanilla extract (containing impurities such as oil and pigments).

Use ethanol for secondary purification to remove wax and obtain high-purity purified oil.

Vanilla Solvent Extraction Advantages: Retain complete aroma molecules, rich flavor layers

200L Herbs Low Temperature vacuum extraction machine for Vanilla Solvent Extraction