botanical extracts lutein astaxanthin

2025-11-29

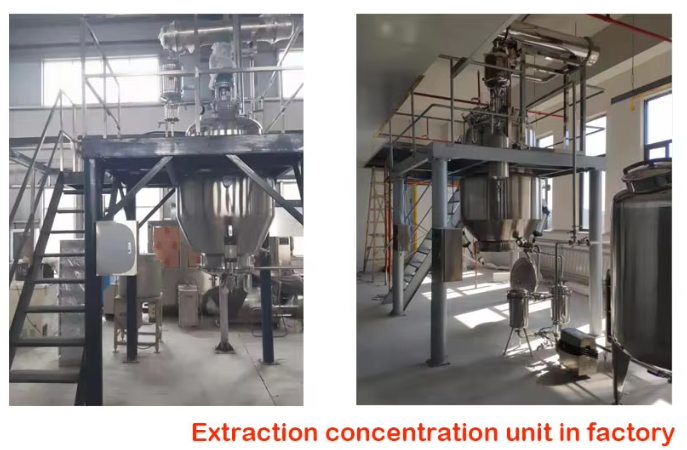

The industrial production of plant extracts lutein and astaxanthin relies on specialized extraction and formulation equipment, including extraction systems, purification devices, and nanocarrier processing machinery. They are mainly produced from marigold and rain red algae as raw materials.

Lutein and astaxanthin in natural plant extracts are high-value carotenoid antioxidants widely used in dietary supplements, functional foods, and cosmetics. Its commercial production requires efficient extraction and enhanced bioavailability from specific plants or microalgae, which cannot be achieved without modern extraction and formulation equipment

Lutein is mainly extracted from marigold petals, while astaxanthin relies on large-scale cultivation of rain grown red algae under light induced stress

Key production botanical extracts lutein astaxanthin equipment and technology process extraction equipment

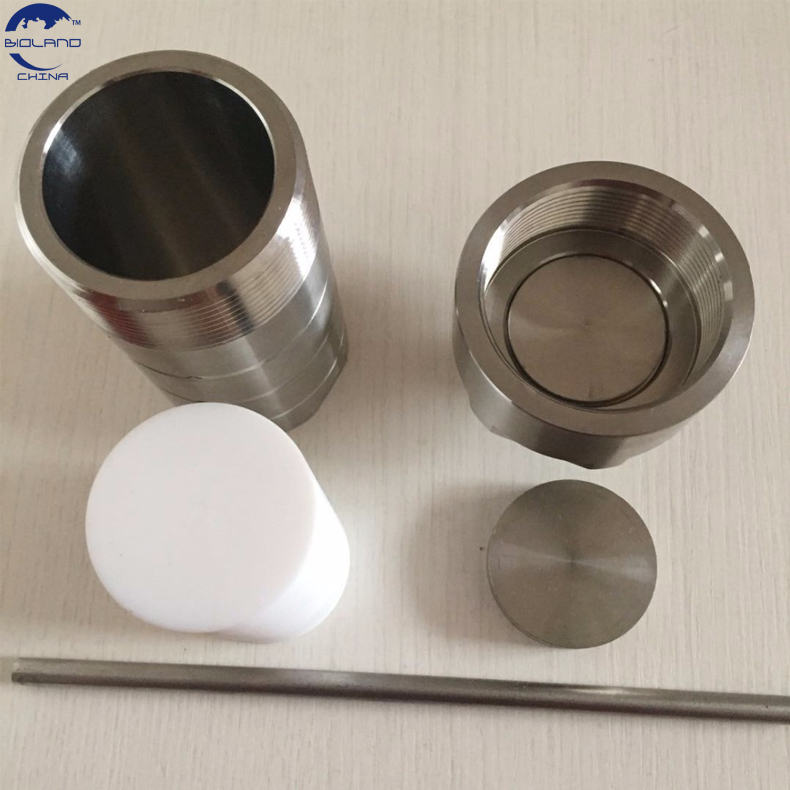

Supercritical fluid extraction system : used for green and efficient extraction of lipophilic carotenoids, avoiding residual organic solvents.

Ultrasonic assisted extraction device: improves cell wall breaking efficiency and enhances extraction rate.

Photobioreactor (IPBR): specifically designed for high-density cultivation of Haematococcus pluvialis, regulating parameters such as light, CO ₂, pH to promote astaxanthin accumulation.

Formulation and Efficiency Enhancement Technology

Nano vesicles system: It can encapsulate lutein into nanoparticles, significantly improving its gastrointestinal stability and absorption rate (increasing in vitro permeability by about 70%).

Spray dryer/fluidized bed granulator: used to prepare powder beadlets or microcapsules for use in the formulation of end products.

Testing and Quality Control

HPLC-UV/VIS analyzer: used for quantitative determination of lutein and astaxanthin purity.

DLS and TEM: Characterization of Particle Size and Morphology of Nanoformulations

100L Herbal Stevia sugar Ultrasonic Extraction Machine