continuous rectification column system

2025-12-09

continuous rectification column system refers to the operational mode in which raw materials continuously enter the distillation column and products are continuously extracted, suitable for large-scale stable production. Compared with intermittent operation, it has higher energy efficiency and more stable product quality.

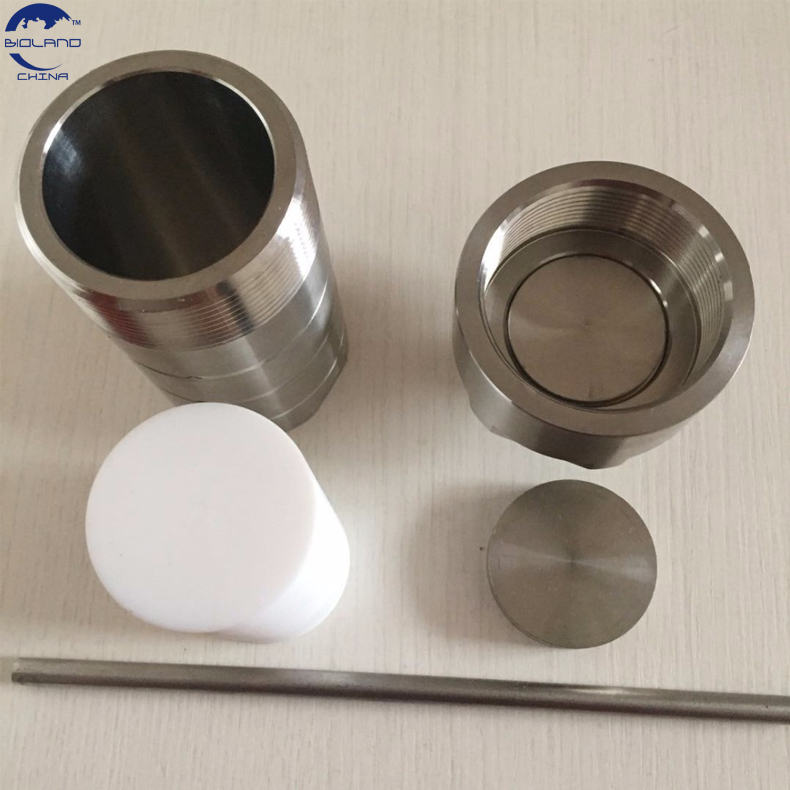

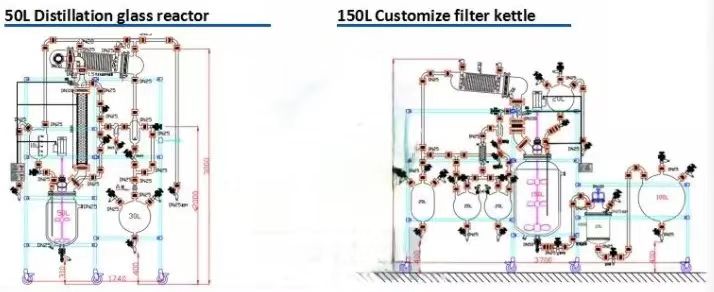

The continuous rectification column system usually includes core components such as tower body, reboiler, condenser, feed preheater, and control system, and can be designed as packed tower or plate tower for different systems

Continuous distillation column system is an efficient device for uninterrupted separation and purification in chemical production, widely used in fields such as petroleum refining, solvent recovery, and fine chemical synthesis

structure and working principle of continuous rectification column system

Distillation columns can be divided into two main types based on their internal components: plate towers and packed towers. Depending on the operating mode, they can also be classified into atmospheric pressure, depressurization, or pressurized operation.

In continuous operation, the gas-liquid phase contacts step by step in the tower, and separation is achieved by utilizing the difference in volatility of each component.

The feed position, reflux ratio, and temperature distribution are key parameters that affect separation efficiency and need to be optimized and controlled to ensure stable product quality.

chemical plant distillation packed column Distillation rectification instrument manufacturers