herbal Concentration and Extraction system

2026-01-06

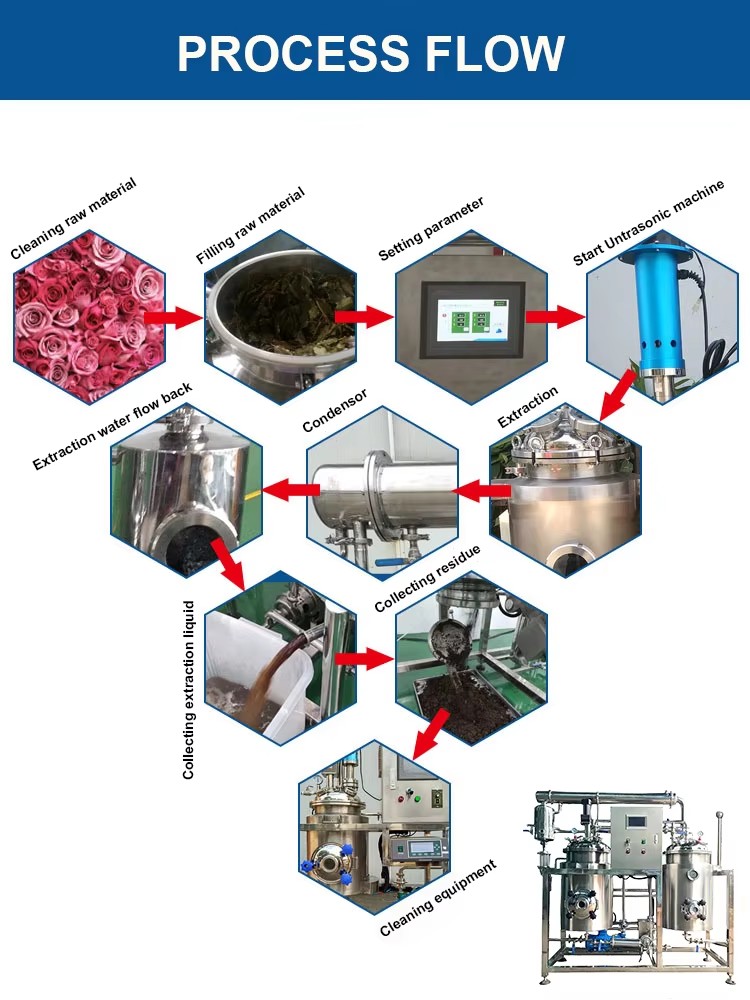

The core of the herbal extraction and concentration system is to separate active ingredients from plant materials through physical or chemical methods and enrich them into high concentration products.

background of herbal Concentration and Extraction system

Herbal extraction and concentration systems are widely used in industries such as traditional Chinese medicine pharmaceuticals, health products, food additives, and natural flavors. This type of system usually combines multiple processes, such as water extraction, alcohol extraction, vacuum concentration, distillation, etc., to efficiently obtain effective ingredients in plants (such as flavonoids, saponins, volatile oils, etc.). Modern equipment often uses stainless steel materials (such as SS304/SS316L), which have the characteristics of automation control, energy saving, and compliance with GMP certification.

A typical herbal extraction and concentration system includes the following core modules:

Extraction tank: used to heat and mix medicinal herbs with solvents (water or ethanol) to dissolve the active ingredients.

Evaporator/Concentrator: Concentrate the extract at low temperature under vacuum conditions to prevent the decomposition of heat sensitive components.

Condenser: Recovers solvent vapor and improves resource utilization efficiency.

Separation device: such as oil-water separator, used to separate essential oils from water phase.

Control system: PLC automatically controls parameters such as temperature, pressure, and time.

Multifunctional Vacuum Concentration and Extraction system for sale