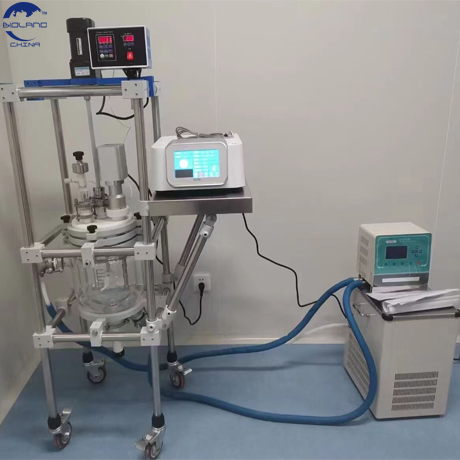

Ultrasonic Crystallization glass reactor

2025-12-22

A Ultrasonic Crystallization glass reactor with ultrasonic crystallization function, which accelerates crystal nucleation, controls particle size, and optimizes morphology by integrating ultrasonic probes or reaction chambers.

Ultrasonic Crystallization glass reactor is a technique that utilizes ultrasonic cavitation to promote or regulate the crystallization process. It can significantly shorten the induction period, increase nucleation rate, improve crystal morphology, and inhibit scaling. By combining this technology with glass reactors,.

Ultrasonic Crystallization glass reactor can be widely applied to the crystallization and purification of high-purity chemicals, pharmaceutical intermediates, etc. in laboratory research and development and pilot production.

Technical mechanism and advantages of Ultrasonic Crystallization glass reactor

The cavitation bubbles generated by ultrasound in liquid release energy when they rupture, triggering a local high-temperature and high-pressure microenvironment, thereby: disturbing the stability of the solution and reducing the nucleation barrier;

Generate strong mixing and shear forces to prevent local supersaturation;

Refine the crystal nucleus to obtain a more uniform particle size distribution.

This "field strengthening" method is more controllable compared to traditional cooling/evaporation crystallization

3500W Industrial Jacketed chemical Ultrasonic Crystallization glass reactor

Consultation