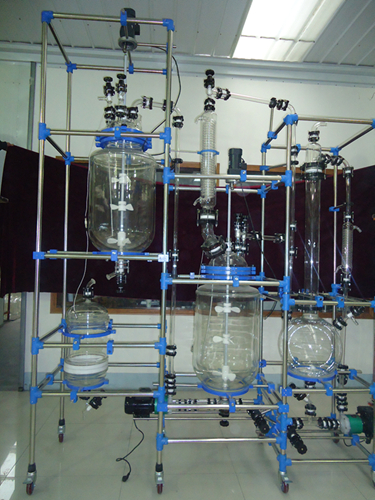

fractionation distillation column 50L Reactor

2026-01-04

Fractionation distillation column reactor "is not a standard term, it may refer to a catalytic distillation device that integrates the functions of distillation, distillation column, and reactor, that is, chemical reactions are carried out simultaneously during the distillation process to improve efficiency.

background of fractionation distillation column 50L Reactor

fractionation distillation column Reactor- In chemical production, "fractionation" refers to the process of separating substances based on their boiling point differences; The distillation column, also known as the distillation tower, is the core equipment for implementing this process; And 'reactor' is a container for chemical reactions to occur. The technology of combining the three is commonly used in catalytic distillation, which involves setting up a catalyst bed inside the distillation tower to promote the reaction while separating.

Technology integration: catalytic distillation reactor

The advantages of this integrated design are:

Synchronize reaction and separation to improve conversion rate;

Reduce by-products, save energy and be efficient;

Support online catalyst replacement (some designs).

For example, fractionation distillation column Reactor in alkylation or esterification reactions, the use of a moving bed catalytic distillation column can enable continuous reaction of hydrocarbon feedstocks and segmented separation of target products

50L chemical fractionation distillation column glass reactor for strong acid alkali