nano spray dryer machine price

Mini Lab 2L Glass Spray Dryer for Make Milk Flavor Powder

Laboratory Chemical Liquid Chemical Powder Spray Dryer

Product Detail

Product Description

- Efficient drying speed: The spray dryer can quickly atomize the liquid into tiny droplets and evaporate quickly in the hot air flow, so it has a high drying speed. This is very important for industrial production processes that require rapid drying.

- Easy to operate and automate: Spray dryers are relatively simple to operate and can be easily integrated with automated systems to increase production efficiency and reduce operator dependence.

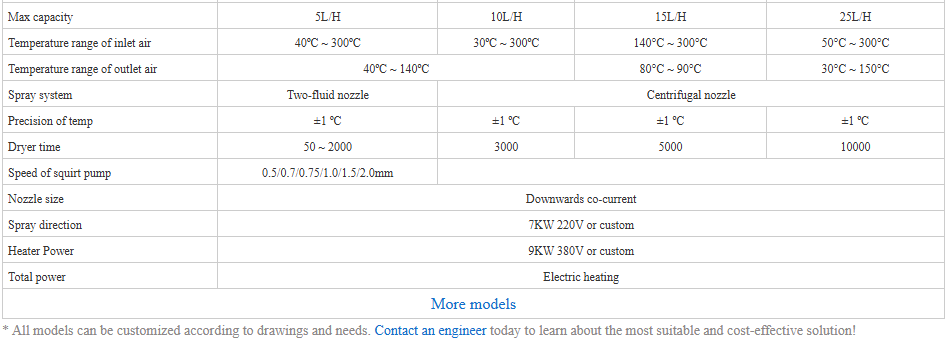

Product Parameters

Spray drying technology has received widespread attention because of its high efficiency, easy control and suitability for a variety of materials, and has important application value in many industries. It has a wide range of applications in various industrial fields:

- Food industry: used for drying dairy products powder, coffee powder, juice powder, spices, protein powder and other food products.

- Medical industry: used for drying preparation of article powders, injection powders, vitamins, herbal extracts and other medicines.

- Chemical industry: used for drying chemical products such as dyes, pigments, catalysts, plastic additives, and detergents.

- Ceramic industry: used to prepare ceramic powder for subsequent molding, sintering and other processes.

- Environmental protection engineering: used to treat organic matter, heavy metals, etc. in wastewater and exhaust gas, and convert them into solid powder or particles for processing or recycling.

- Biotechnology: Used for the drying of biological products such as proteins, enzymes, and cell culture media.

- Agriculture: Used for drying agricultural products such as fertilizers and feeds.

- Nanomaterials: used for the preparation of nanoparticles or the drying of nanomaterials, such as nanoiron oxide, nanosilica, etc.