- Home

- >

- Products

- >

- Sterilization

- UHT Sterilization machine

lab scale Pasteurizer Uht Sterilizer for Tomato Sauce, Flavor Milk, Yogurt, Juice Sterilization

Factory lab scale Pasteurizer Uht Plate Heat Exchanger Sterilizer for Food Processing

The Latest Technology Mango / Pineapple Sauce and Milk Uht Sterilizer

Product Detail

Product Description

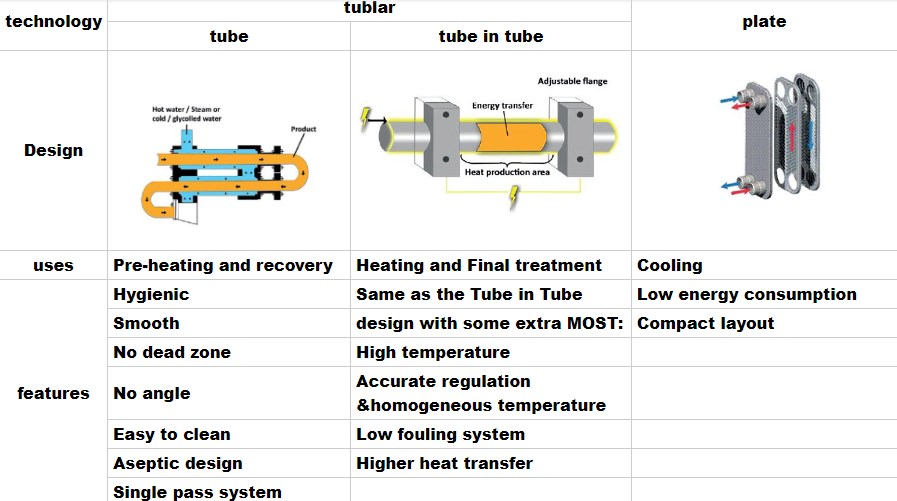

Tubular automatic ultra-high temperature sterilization equipment is professional equipment for an aseptic cold-filling production line. It consists of a plate heat exchanger, tubular heat exchanger, material balance system, material increase system, material cooling system, and steam system. Instantaneous sterilization method, the machine saves energy, the sterilization temperature is constant, the control precision is high, the active ingredient damage is small, and the machine life is long.

Ultra-high temperature processing (UHT) is a food processing technology that sterilizes liquid food by heating it above 135 °C (275 °F) for 2 to 5 seconds. UHT is commonly used in milk production, fruit juices, cream, soy milk, yogurt, wine, soups, honey.

UHT material packaged in a sterile bag, if not opened, has a typical refrigerant shelf life of six to eighteen months.

Main Features of UHT sterilizing Machine:

- The temperature difference between heating medium and materials is small, which can realize mild heating.

- The heat exchange pipe is made of multi-user, with mirror polishing and less scaling, increasing the lifetime of sterilizer.

- High degree of automation. The whole process from CIP cleaning, sterilization to material sterilization can be automatically

controlled and recorded.

- Accurate and reliable sterilization temperature control: the system influencing the sterilization temperature, such as steam

pressure, flow rate and material flow rate, are strictly controlled automatically.

- The inner wall of the material pipe is polished with advanced automatic welding technology.