- Home

- >

- Cases

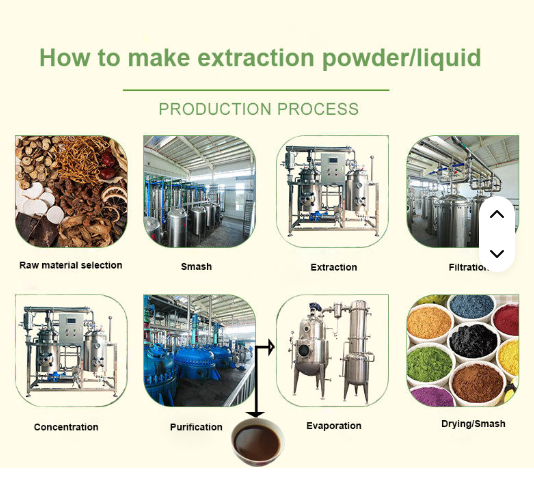

Rosemary extraction technological process

The extraction process of rosemary mainly includes core steps such as raw material processing, solvent or supercritical extraction, concentration and purification, and drying. The specific process varies depending on the target product (such as antioxidants, essential oils, or acidic components).

Rosemary is rich in various active ingredients, such as oxalic acid, rosmarinic acid, rosmarinol, and essential oil. The extraction process of rosemary needs to choose the appropriate method based on the solubility (water solubility or fat solubility) of the target ingredients. Common extraction methods include organic solvent extraction, supercritical CO ₂ extraction, steam distillation, and auxiliary techniques such as ultrasound or enzymatic hydrolysis. Different processes have their own advantages and disadvantages in terms of efficiency, purity, cost, and environmental protection.

Main extraction methods and processes

Traditional organic solvent extraction method

After crushing the raw materials, perform hot reflux extraction with ethanol or aqueous ethanol.

The extract is filtered, concentrated, decolorized, and spray dried to obtain the extract or powder. Suitable for large-scale production, but there may be solvent residue issues.

Supercritical CO ₂ extraction method

By utilizing the high permeability and solubility of CO ₂ under high pressure, selectively extract lipid soluble components such as essential oils and antioxidants. Carriers (such as ethanol) can be added to improve the extraction rate, resulting in high purity and no solvent residue in the product. Large equipment investment, suitable for high-end product production.

steam distillation

It is mainly used to extract rosemary essential oil. Volatile components are taken out by steam and collected by condensation. It can be combined with enzymatic pretreatment (such as cellulase) to destroy cell walls and increase oil yield to 4.1%.

Assisted Extraction Technology

Ultrasonic assisted: Utilizing cavitation effect to accelerate solvent penetration and shorten extraction time. Enzymatic assisted hydrolysis: first using enzymes to degrade plant cell walls, and then solvent or distillation extraction can significantly improve yield

Component separation and purification methods

The extracted crude extract can be further separated into water-soluble and lipophilic components through filtration, centrifugation, resin adsorption, and other methods: 1. Filtration treatment - Plate and frame filter

2. Filtrate treatment - high-speed centrifugation → double effect concentration → spray drying → crushing.

Rosmarinic acid is a water-soluble antioxidant component, which is often purified by deep filtration using macroporous resin combined with membrane filtration; Fat soluble antioxidants, mainly oxalic acid, are extracted through organic solvents or supercritical CO ₂ extraction