- Home

- >

- Products

- >

- Extraction

- essential oil distiller

1000L best essential aromatic oil distiller for essential oil making

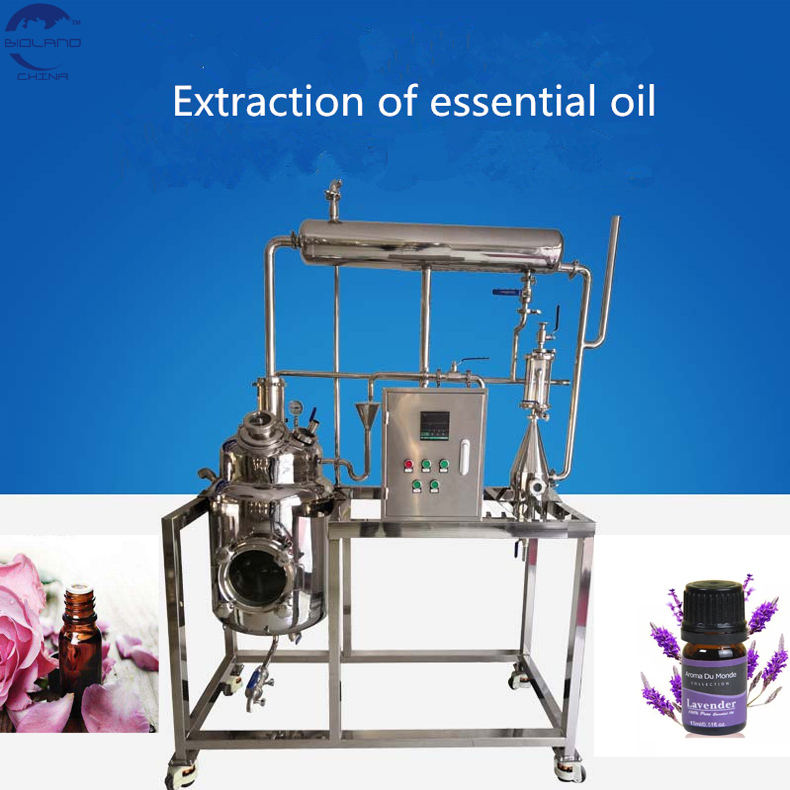

1000l Herbal Steam Distillation best essential aromatic oil distiller, essential oil making machine

Hemp Rose Steam Distillation Machine Plant Essential Oil,best essential aromatic oil distiller, essential oil making machine

Product Detail

Product Description

Our best essential aromatic oil distiller or essential oil making machine can be used for health products, biological drugs, cosmetics, and food. This uses technology and chemical separation can extract plant components efficiently by steam distillation and have a good effect in collecting essential oil from plants.

essential aromatic oil distiller equipment can be also used for various process operations in the traditional Chinese medicine, food, and chemical industries, including atmospheric pressure, micro pressure, water decoction, warm soaking, hot reflux, forced circulation, percolation, aromatic oil extraction, and organic solvent recovery.

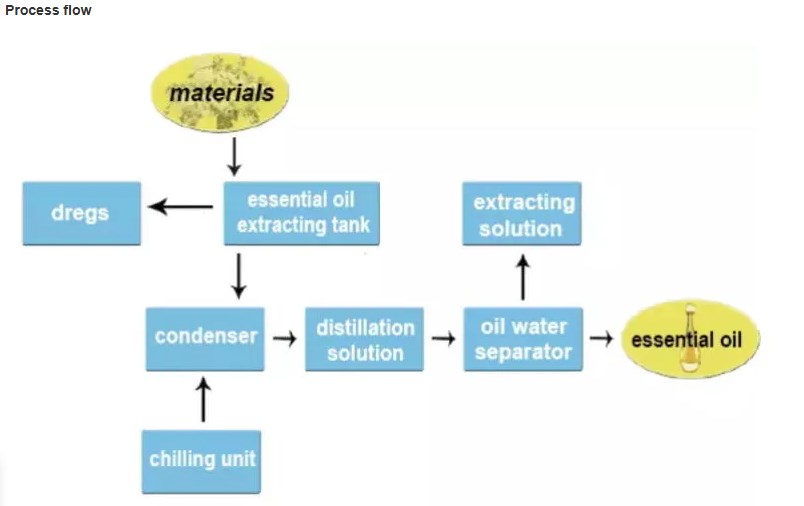

The function of the distillation tank is to heat the liquid to boiling, make use of the difference in the volatility of each component in the mixture to vaporize, and then condense into the liquid process, so that it can achieve the purpose of component separation and purification.

Characteristics of plant aromatic oil extraction equipment:

1. The small multifunctional extraction and concentration unit has complete functions and can obtain full system vacuum, which can meet 11 extraction requirements including volatile oil extraction, water extraction, alcohol extraction, animal visceral extraction, staged extraction, and hot (temperature) reflux extraction;

2. The extraction solution can be concentrated, the paste can be collected, and the organic solvent can be recovered

3. This device can use vacuum low-temperature extraction to effectively reduce the loss of thermosensitive active ingredients. The extraction tank is equipped with two-stage stirring to ensure that the larger volume of materials come into full contact with the solvent, accelerating the precipitation of effective ingredients.

4. The small multifunctional extraction and concentration unit adopts a special structure in the concentration system, which enables the final density of the product to reach 1.4 and the discharge to be smooth;

5. Concentrated liquid material: this equipment can adopt the combination of external heating natural circulation and vacuum negative pressure evaporation, with fast evaporation speed and concentration ratio up to 1.3. The liquid material has no foam concentration in the fully sealed state. The concentrated liquid with this equipment has the characteristics of no pollution, strong medicine flavor, and easy cleaning (open the upper and lower covers of the heater to clean).

Product features 1. The desired product can be obtained directly through the distillation operation of the distillation tank. Unlike extraction, it does not require additional absorbent or extractant to further separate the extracted component from the additional component, so the distillation operation is relatively simple. 2. Distillation separation has a wide range of applications, not only to separate liquid mixtures, but also to separate gaseous or solid mixtures at normal temperature and pressure by changing the operating pressure after liquefaction.

Product application

It can be used to distill the ethanol, methanol and other organic solvents, but also widely applied in the production of essential oils and aromatic plants pure dew (mint, chamomile, cinnamon, sage, lavender and vanilla, orange flower, grass, patchouli, Bulgarian rose, rosemary, rosewood, sandalwood, tea tree, verbena, geranium, ginger, cypress, etc.), It can also be used for the extraction of chemical components of traditional Chinese medicine (ephedrine, aesculolide, etc.).