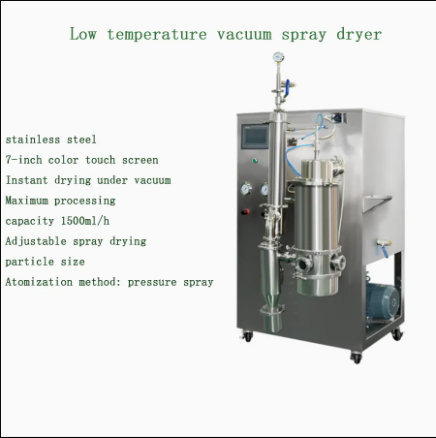

Powder making vacuum Spray Dryer

low temperature Vacuum Spray Dryer for Heat-Sensitive Material

Feed Additive Centrifugal Spray Dryer Medicine ,Low Temperature Spray Drying Chemical Powder Dryer

Product Detail

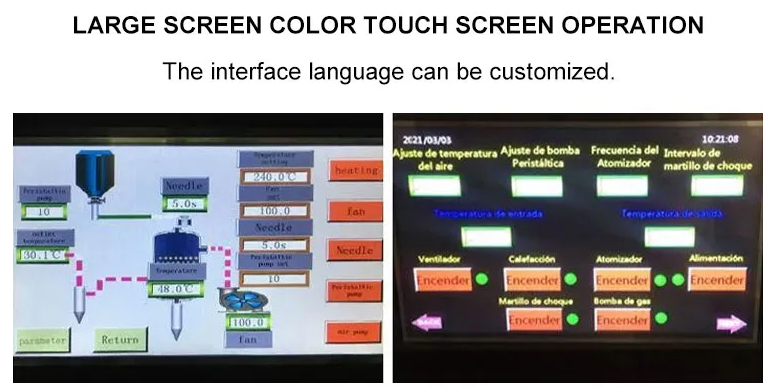

Product Description

Why need vacuum spray dryer?

The rapid drying of heat-sensitive material has been troubling plenty of researchers. Common vacuum drying and spray drying cause great damage to biological activity or structure of material. Freeze drying has disadvantages such as long drying time and low energy efficiency. Moreover, the material after freeze drying is lumpy and needs to be smashed a second time.

The spray dryer is the widely used technology in the liquid shaping technology and drying industry.Lt is most suitable for producing powder, particle solid products from materials of solution, emulsion, solidus and culpable paste states, Therefore, when the particle size of the distribution final products, the residual water contents, the stocking density and the particle shape meet the precision standards, the spray dryer is one of the most desired technologies.

What can vacuum spray dryer do?

Our company after long-term communication with researchers realizes that low-temperature spray drying is able to solve the problems of drying of heat-sensitive material effectively. Therefore, we developed the low-temperature spray dryer for laboratory. The dryer not only inherits many advantages of mini spray dryer, but also integrates the merits of vacuum drying creatively. It is capable of drying material rapidly (1 second) when the temperature of inlet air is around 50ºC. The damage to activity or structure of material during drying is completely prevented. It is a convenient and safe method for drying heat-sensitive material, such as biological products (e.g. enzyme preparation and viable bacteria), extract of natural product from traditional Chinese medicine with high sugar content, heat-labile high polymer material, and material that gasifies when contacting with heat.

Temperature protection : The heater has an extreme high temperature when experiment finished, which needs air blower to continue working in order to reduce the inside temperature and ensure the safety of equipment, low temperature spray dryer can control air blower running automatically, even the operator wants to turn off the air blower, the system would prevent the operator until the temperature of system reduce to the default security state of system ;

SUS 304 stainless steel Spray chamber, cyclone separator, collector are all made of SUS 304 stainless steel . It can work in a no-pollution and stable environment, and sight glass equipped so the whole process can be inspected. All the spare parts are easy to install and clean.

Trusted by the users: Over 1,500 domestic customers of top universities, enterprises and research institutes use our mini spray dryer. And exported to more than 40 countries & regions such as the United States, Italy, South Korea, Mexico,Singapore, Canada, Malaysia, Chile and Russia etc.

Wide range of applications

vacuum spray dryer can be used in a wide range of applications where the production of a free-flowing powder sample is required.This technique has successfully processed materials in the following areas:

Oxide • Blood • Polymers and Resins

Beverages • Flavours & Colourings

Milk & Egg Products • Plant & Vegetable Extracts

Pharmaceuticals • Heat Sensitive Materials

Plastics • Perfumes • Dyestuffs

Ceramics & Advanced Materials

Soaps & Detergents •Textiles

Foodstuffs • Adhesives

Bones, Teeth & Tooth Amalgam and many others