- Home

- >

- Products

- >

- Filtration & Seperation

- nutsch filter

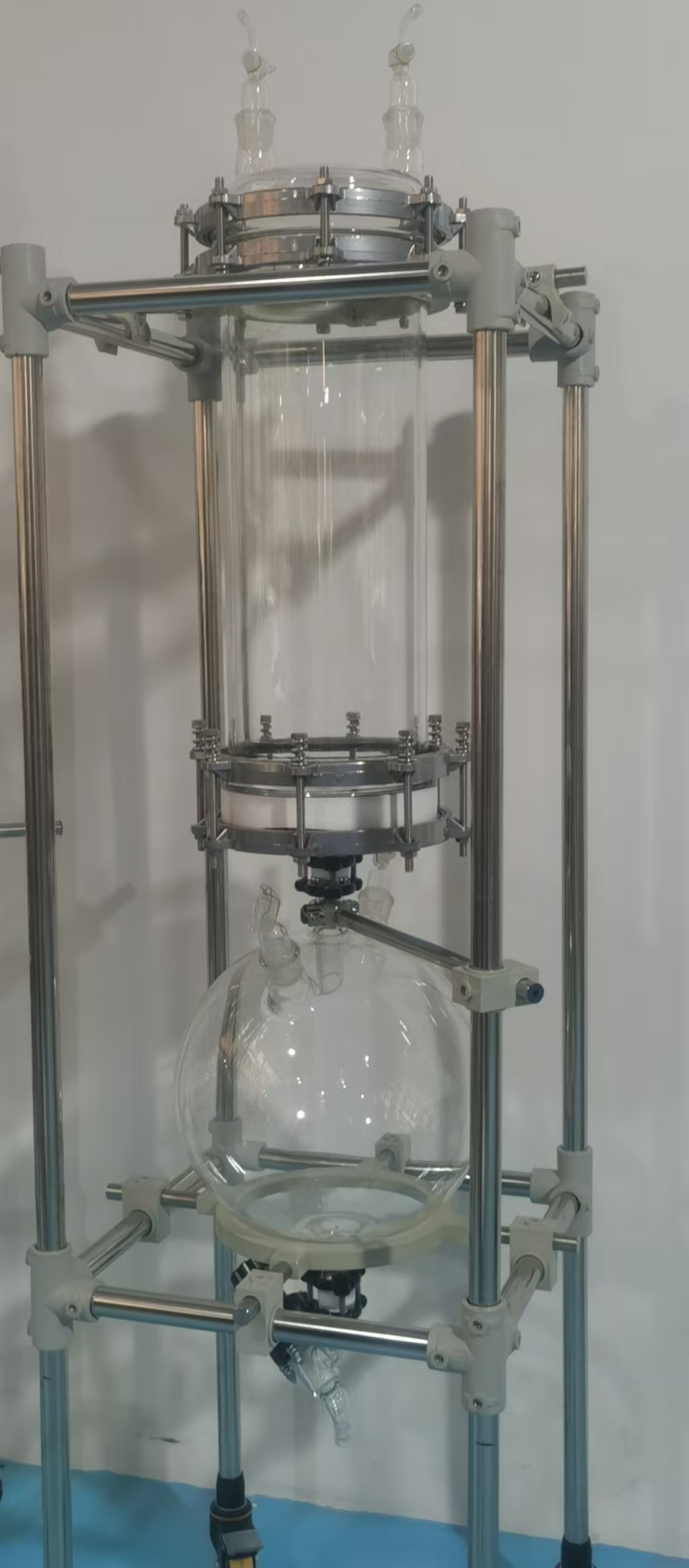

High Quality Vacuum Agitated Nutsch Filter Dryer for Cake

High Quality GMP Vacuum Agitated Nutsch Filter Dryer with Paddle Agitated

Lab Industrial Filtration Equipment Nutsch Filter Dryer

Product Detail

Product Description

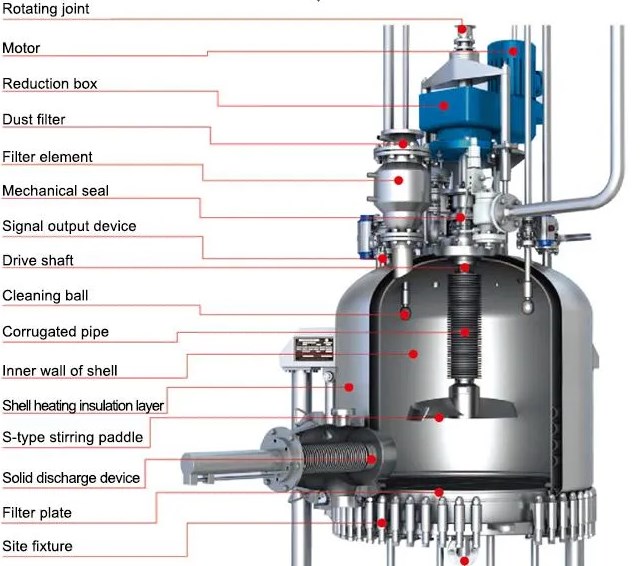

The Vacuum Agitated Nutsch Filter Dryer equipment is a stainless steel vertical container, consisting of tank device, stirring device, shaft end sealing device, lifting mechanism, hydraulic device, tank base (fixed or detachable), heating device, transmission mechanism, filter device, unloading device , sampling device, washing (cleaning) sterilization device, travel knowledge device, touch screen and manual operation control device, hydraulic pump station, main electric control cabinet (including inverter, PLC, etc.), and other electrical accessories and other components. Realize the integration of machine, electricity and instrument.

Vacuum Agitated Nutsch Filter Dryer Equipment Process Characteristics

The whole process of filtration, washing and drying is completed continuously in the same container.

a. Filtration: operate under vacuum to achieve solid-liquid separation. During filtration, the filter cake is flat, and the solid-liquid separation effect is good.

b. Washing: There is a 360° rotating spray device on the inside of the container, so that the cleaning (washing) liquid is evenly distributed in the container, which can realize the cleaning inside the container and the paddle washing of materials, and the filter cake and the washing liquid are mixed by stirring the lifting paddle. , so that the slurry crystal and filter cake can be fully washed.

c. Drying: The filter cake is loosened layer by layer by the stirring blade, the heating device of the equipment evenly heats the filter cake, and the wet material is heated with hot gas in a vacuum state to accelerate the evaporation and achieve the purpose of drying.

d. Unloading: Scrape and loosen the material, and push it through the stirring blade to automatically unload the material from the discharge port on the side of the tank wall.

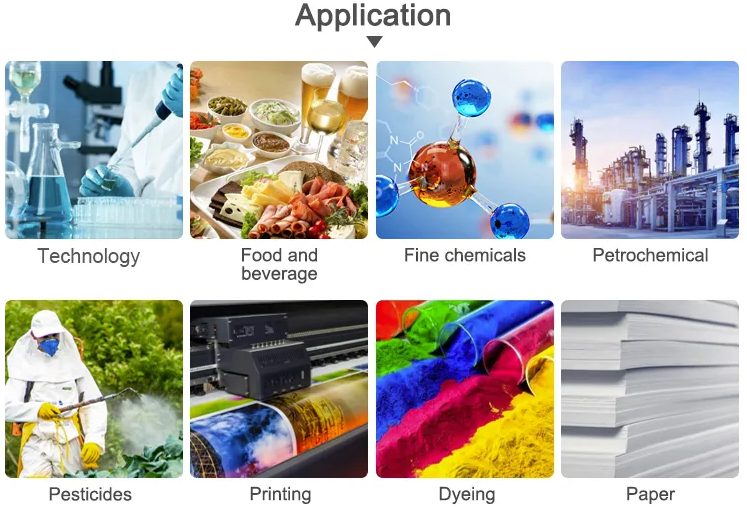

Application

NFD series filtration, washing and drying machines (also known as tank-type three-in-one) are widely used in solid-liquid separation, solid washing, solid drying and solid unloading in the pharmaceutical, chemical, pesticide, food and other industries. The whole process can be closed The continuous operation is the selection equipment for filter washing and drying in the above industries.