- Home

- >

- Products

- >

- Filtration & Seperation

- nutsch filter

Stainless Steel 100L Critical Operation Agitated Nutsche Filter Dryer

Multifunction Agitated Hastelloy Dryer Equipment Filtering Washing Drying Equipment

Chemical Pharmaceutical Machinery Anfd Pharmaceutical Nutsche Filter Dryer

Product Detail

Product Description

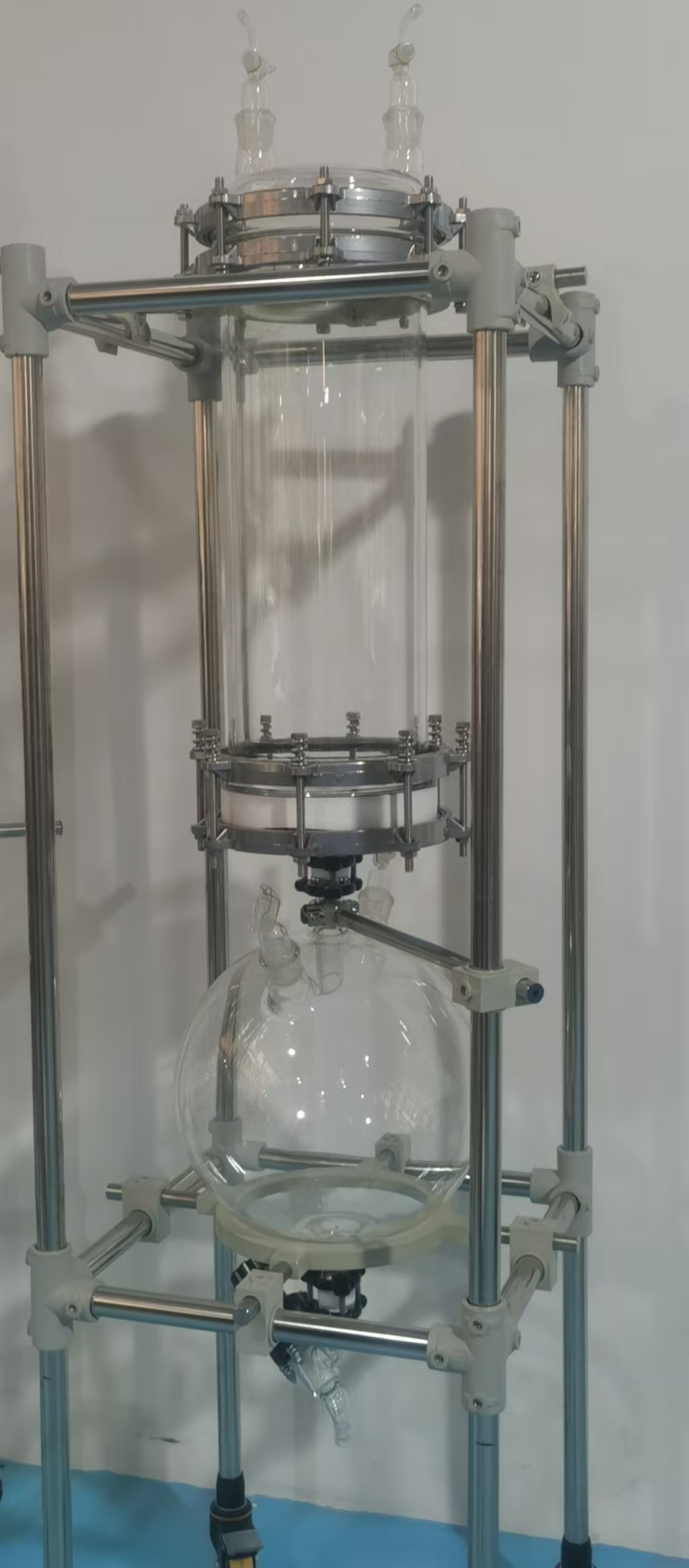

The Nutsche filter dryer combines two process operations, filtration, and drying, in a single piece of equipment. Filtration liquid-solid separation and agitated vacuum drying allow batch manufacturing of chemical and pharmaceutical products. Filter dryers can also be used for another process such as vegetal extraction.

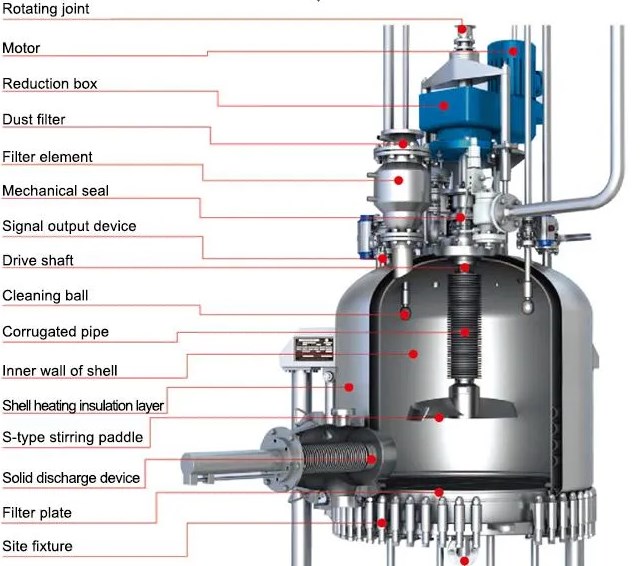

Process and structure

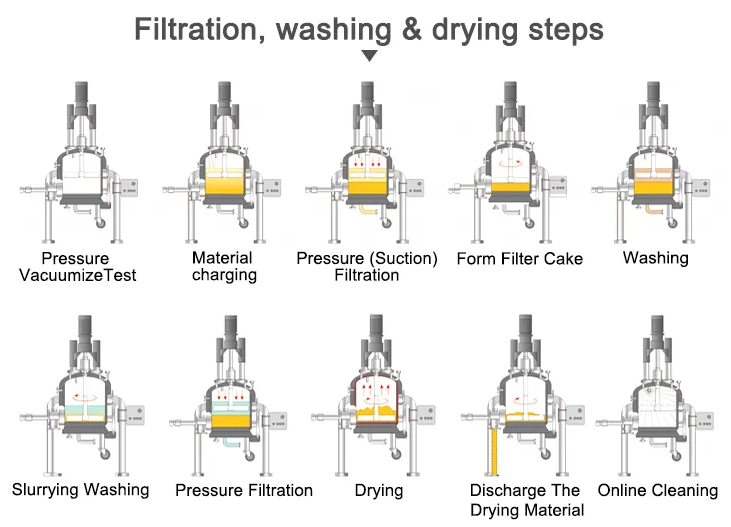

Filtering stage: The separation of filter cake and mother liquid. The thickness of the filter cake can reach 500mm.

Washing stage: Further purification of filter cake, rinse, and dehydration of mother liquid remained. Mix the lotion and the filter cake via the up and down of the agitator to make the filter cake slurry finally, then the filter cake can get the full wash.

Drying stage: Dehydrating and drying the filter cake. The agitator will scrape the filter cake loose by layers while the sidewall; the bottom of the filter plate and the agitator will heat the filter cake at the same time. Moreover, the vacuum inside the equipment will accelerate the evaporating speed; the entered hot nitrogen will take away the dampness and accelerate the speed of desiccation.

Applications

Applications:It is widely applied in the industries, such as pharmaceutical, chemical engineering, agrochemical, food, etc. It can realize the continuous operation in vacuum, and even more suitable for producing sterile and poisonous products.