- Home

- >

- Products

- >

- Distillation

- Short-path molecular distillation

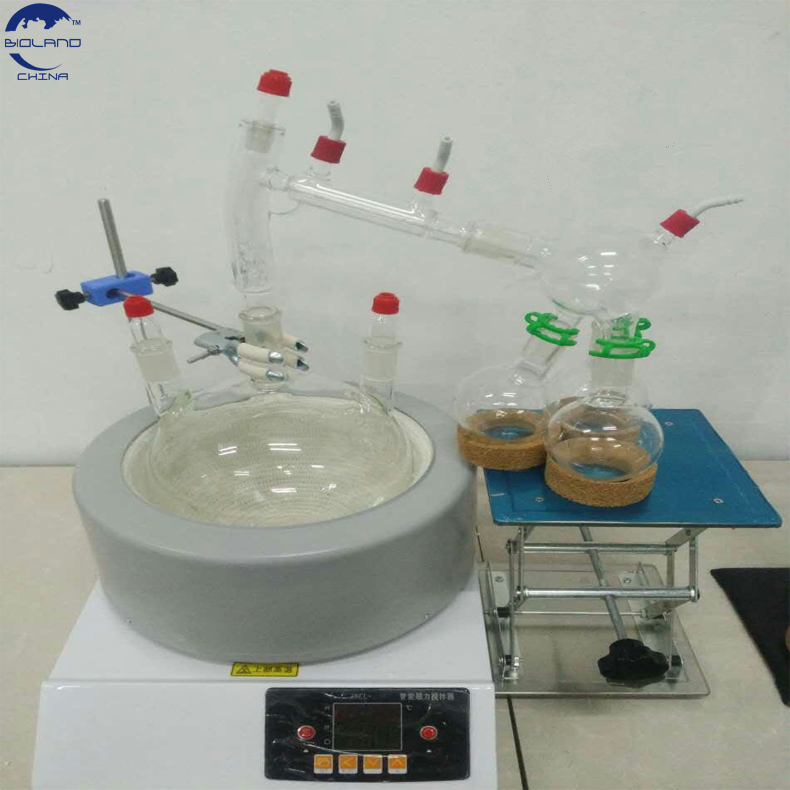

Molecular Shortpath Lab Glassware Kits Evaporator

Short Path Distillation Lab 2L 5L Molecular Distillation

Short Path Molecular Fractional Distiller Chemical Glass Distillation System

Product Detail

product description:

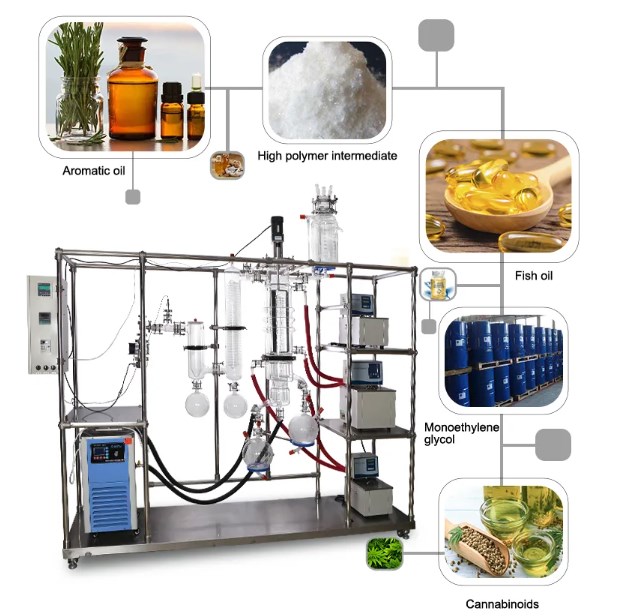

molecular distillation, also called molecular distiller, it is a process of separation, purification and concentration of natural products, complex and thermally sensitive molecules for example vitamins and polyunsaturated fatty acids.Molecular Distillation is a special liquid-liquid separation technology, which is different from traditional distillation on the difference boiling point. This is a kind of distillation in high vacuum environment, for the difference of material molecular movement free path, was carried out in the heat sensitive materialor high boiing point material distillation and purification process. Short Path Distillation is mainly used in chemical, pharmaceutical, petrochemical,spices, plastics, oil and otherfields.

Principle of Molecular Distillation:

1. Molecules diffuse from the main body of the liquid phase to the evaporation surface: Generally, the diffusion speed in the liquid phase is the main factor controlling the molecular distillation speed, so the thickness of the liquid layer should be minimized and the flow of the liquid layer should be strengthened.

2. Free evaporation of molecules on the surface of the liquid layer: the evaporation rate increases with the increase of temperature, but the separation factor sometimes decreases with the increase of temperature, so the thermal stability of the processed material should be the premise , Choose an economical and reasonable distillation temperature.

3. Molecules fly from the evaporation surface to the condensation surface: When the vapor molecules fly from the evaporation surface to the condensation surface, they may collide with each other, or they may collide with air molecules remaining between the two surfaces. Since evaporation molecules are much heavier than air molecules, and most of them have the same direction of motion, their collisions have little effect on the direction of flight and the speed of evaporation. The residual gas molecules are in chaotic thermal motion between the two sides, so the number of residual gas molecules is the main factor that affects the direction of flight and the evaporation speed.

4. Molecules condense on the condensing surface: as long as there is enough temperature difference between the hot and cold sides (generally 70~100ºC), and the form of the condensing surface is reasonable and smooth, it is considered that the condensation step can be completed instantly, so choose a reasonable condenser The form is very important

Industry Application

It is mainly used for the L- lactic acd and other organic acids production.