- Home

- >

- Products

- >

- Distillation

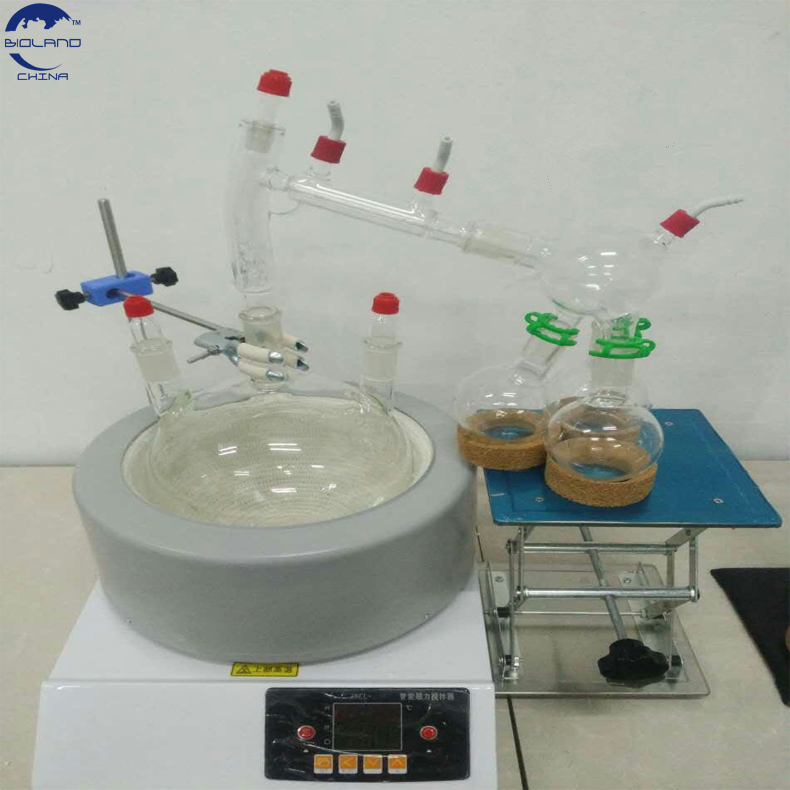

- Short-path molecular distillation

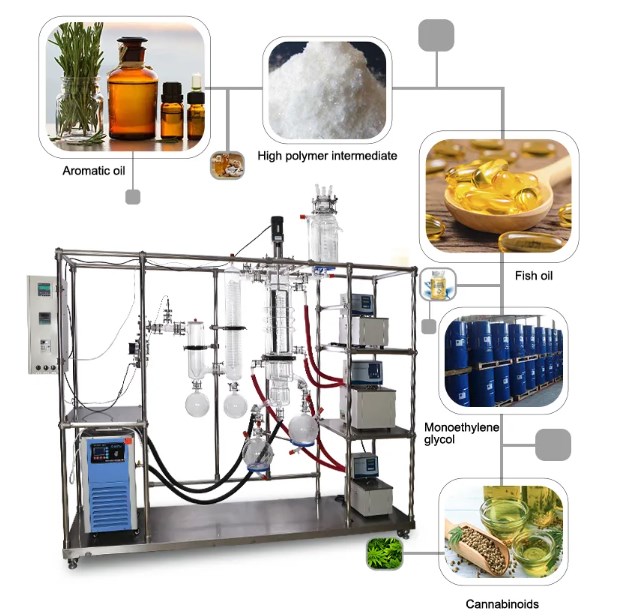

Industrial Short Path Molecular Distillation Oil Distiller for High Purity Hemp Oil

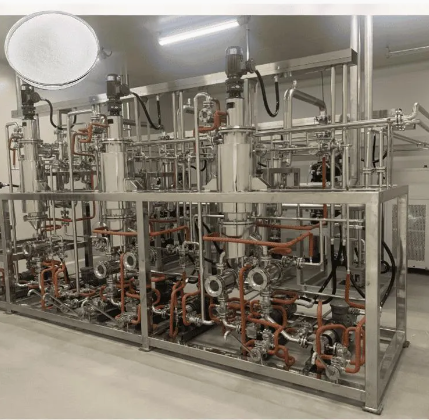

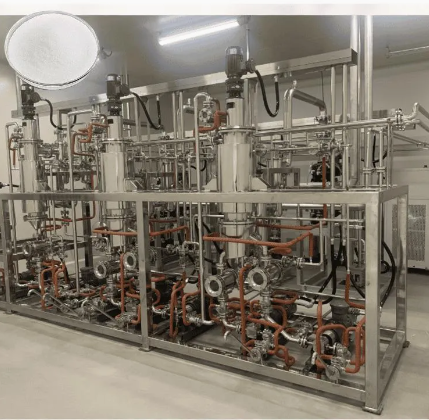

Industrial Short Path Molecular Distillation for High Purity Hemp Oil

Continuous Wiped Film Evaporator Short Path Molecular Distillation Oil Distiller

Product Detail

Product Description

Molecular (wiped film) distillation is the best thermal separation machine for heat-sensitive material because it is the gentlest type, causing the least amount of thermal degradation of the product. It is a process of separation, purification, and concentration of natural products, complex and thermally sensitive molecules. Molecular distillation is mainly used in chemical, pharmaceutical, petrochemical, spices, plastics, oil, and other fields.

Feature

(1) Low operating temperature can greatly save energy consumption

Conventional distillation relies on the difference of boiling points of different substances in the material mixture for separation, while molecular distillation relies on the difference of Mean free path of molecular motion of different substances for separation, which does not require that the materials must reach boiling state, and separation can be achieved as long as the molecules volatilize from the liquid phase. Because molecular distillation operates far from the boiling point, the energy consumption of the product is low.

(2) The distillation pressure is low and requires operation under high vacuum.

The Mean free path of molecular motion is inversely proportional to the system pressure. Only by increasing the vacuum, can we obtain a sufficiently large Mean free path. Research has shown that the vacuum degree of molecular distillation can reach as high as 0.1-100Pa.

(3) Short heating time reduces the thermal damage of heat sensitive substances.

Since molecular distillation realizes separation by making use of the difference in the Mean free path of molecular motion of different substances, its basic requirement is that the distance between the heating surface and the condensation surface must be less than the Mean free path of the movement of light molecules. This distance is usually very small, so light molecules escape from the liquid surface and shoot towards the condensation surface almost without collision, so the heating time is extremely short. Research has shown that the heating time of molecular distillation is only a few seconds or tens of seconds, thus greatly avoiding the decomposition or polymerization of substances.

(4) High separation degree and product yield, especially suitable for specific distillation

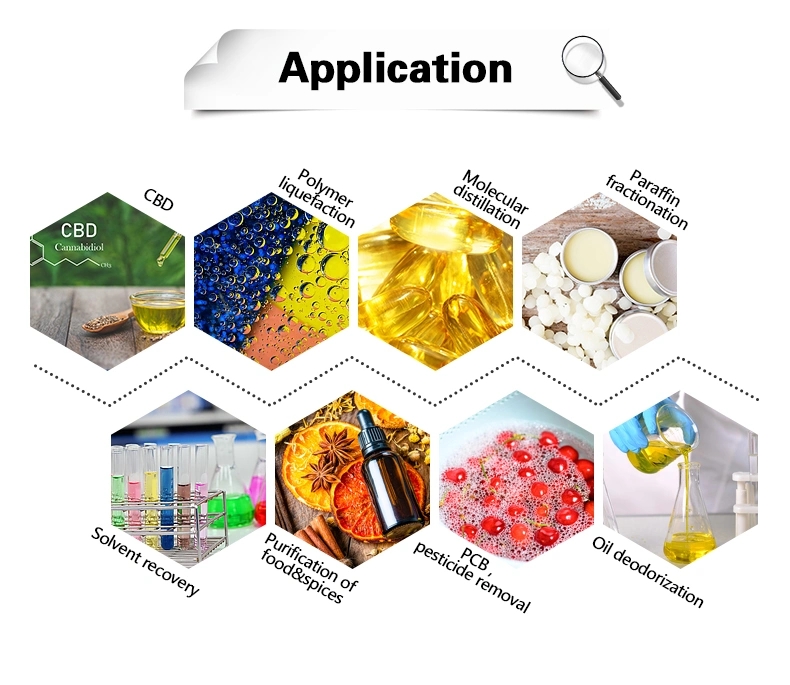

Application

1. Petrochemical industry. In petrochemical production, researchers have successfully used molecular distillation technology to treat silicone oil, polyethylene glycol, polyethylene glycol ether, acrylonitrile, amine, bisphenols, Caprolactam, Cumene peroxide, dioctyl Phthalic acid, epoxy resin, glycol, rosin, etc. Alexander et al. also successfully utilized molecular distillation technology to recover waste engine oil and obtain high-grade lubricant raw materials from petroleum.

2. Oil processing. At present, molecular distillation technology is mainly applied in the separation, purification, and distillation of oils and fats. For example, separation of pesticides from fat lotion, deodorization of cosmetics and spices, separation of monomer from silicone oil, manufacture of glycerol ester emulsifier from esterification containing triglycerides, separation of various chain fatty acids, and distillation of epoxy resin.