Stainless Steel Ultrasonic Biodiesel Reactor

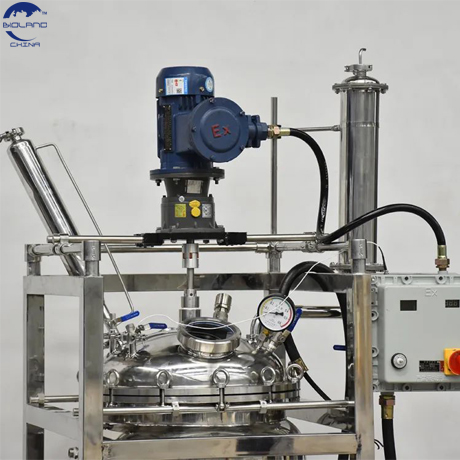

Stainless Steel Ultrasonic Biodiesel Reactor -Laboratory Scale stainless steel 20L 50L Ultrasonic Chemical Jacketed Reactor

Stainless Steel Ultrasonic Biodiesel Reactor ,Ultrasonic Chemical Reactors Glass & Stainless Steel Reactor

Product Detail

Product Description

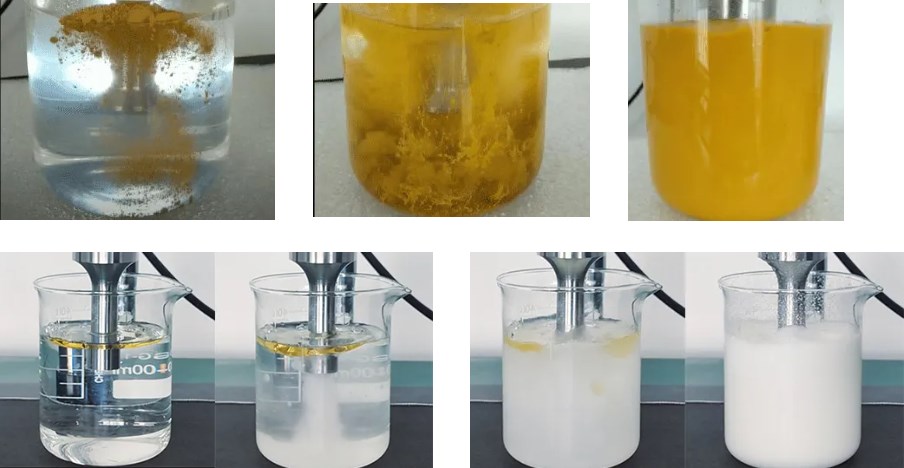

Stainless Steel Ultrasonic Biodiesel Reactor use the cavitation of ultrasonic to disperse the coacervate particle. It put the required processing of particulate suspension (liquid phase) in the super sound field, use appropriate ultrasonic amplitude and duration to process.

Due to the inherent characteristics of powder particles coacervate, so for some powder which could not be dispersed well in medium, you could add the right amount of dispersant to keep the dispersed steady-state, general could reach dozens of nanometers, even more small.

These obvious advantages of ultrasonic emulsification have prompted it in food, chemical, pharmaceutical, textile, paper making, paint, fuel thermal power, fuel central air conditioning, petroleum, metallurgy, and many other industrial processes has been applied more and more, including down fuel combustion is an important project to rise.

Ultrasonic reactor is the use of ultrasonic dispersion, crushing, activation and other multiple effects to destroy the solvent structure, improve the reaction activity, disperse crushed particles, to futher reduce the diameter of the wire. The test proved that: ultrasonic reactor play a significant role in the superfine grinding, oil emulsification extraction and dispersed in nano scale for the powder material in liquid phase. At the same time, it can accelerate the reaction, emulsifying reaction and homogeneous reaction of powdery substance.