50l Biodiesel Ultrasonic Chemical Reactor for Biodiesel

Industrial 20L 50L 100L Ultrasonic Nanoparticle Dispersion Homogenizer Lab Chemical Reactor

Biodiesel Production Ultrasonic and Microwave Flow Cell Crystallization Glass Reactor

Product Detail

Product Description

ultrasonic series instruments use the cavitation of ultrasonic to disperse the coacervate particle. It put the required processing of particulate suspension (liquid phase) in the super sound field, use appropriate ultrasonic amplitude and duration to process.

Due to the inherent characteristics of powder particles coacervate, so for some powder which could not be dispersed well in medium, you could add the right amount of dispersant to keep the dispersed steady-state, general could reach dozens of nanometers, even more small.These obvious advantages of ultrasonic emulsification have prompted it in food, chemical, pharmaceutical, textile, paper making, paint, fuel thermal power, fuel central air conditioning, petroleum, metallurgy, and many other industrial processes has been applied more and more, including down fuel combustion is an important project to rise.

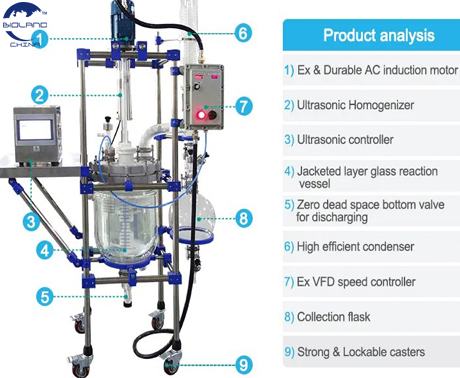

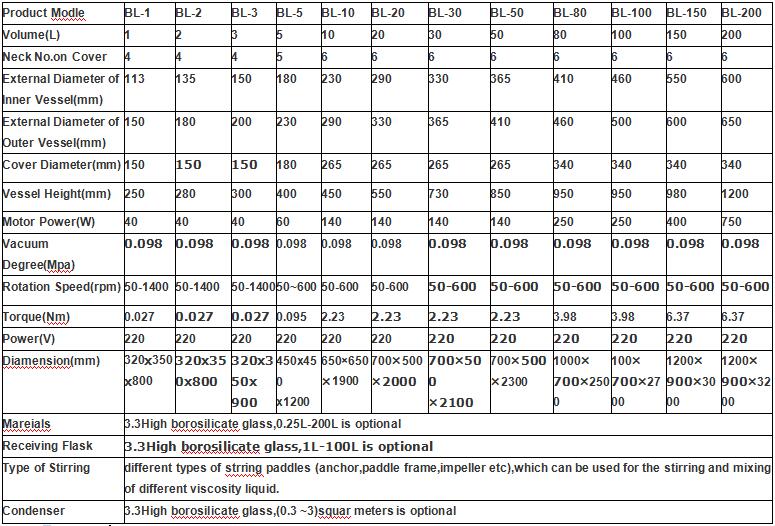

Product Parameters

ultrasonic double layer glass reactor adopts double-layer glass design. The reaction solvent can be put in the internal layer to do the stirring reaction, and different cold and heat sources (refrigerating fluid, hot water or oil) can be connected to the interlayer to do the circulating heating or cooling reaction. And the ultrasonic device is equipped, which can save solvent, speed up the reaction process, enhance both the extraction rate and the dissolution rate. At a constant temperature, the stirring reaction can be done under normal or negative pressure, as well as the backflow and distillation of the reaction solution. It is an ideal pilot-plant and production equipment for modern fine chemical industry, biopharmaceutical and new material synthesis.

Application

An ultrasonic double layer is an ideal equipment for lab-scale and pilot tests, biopharmaceutical, new drug research and development and new material synthesis. It is primarily used in small chemical industry, petroleum, metallurgy, coal, electronics, building materials, light industry and other fields, or the medium and small scale production.

Project Case