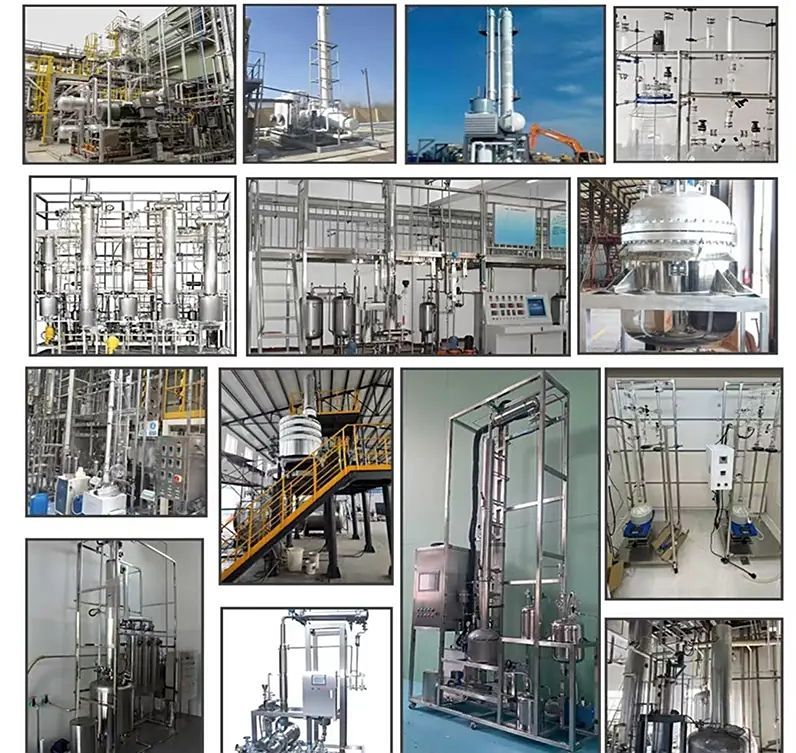

glass distillation column tower of chemicals purification

glass distillation column tower -Produce high-purity chemicals fractionating glass distillation column tower

fractionating column Distillation tower is a tower type vapor-liquid contact device used for distillation

Product Detail

Product Description

A glass distillation column tower utilizes the property that each component in a mixture has different volatility, that is, the vapor pressure of each component is different at the same temperature, to transfer light components (low boiling substances) from the liquid phase to the gas phase, and heavy components (high boiling substances) from the gas phase to the liquid phase, thereby achieving the purpose of separation. Distillation tower is also a widely used mass and heat transfer device in petrochemical production.

technological process

In petrochemical production, it is often required to obtain products with high purity, which can be obtained through distillation process.

The equipment used in the distillation process is called a distillation tower, which can be roughly divided into two categories: ① Plate tower, where the gas-liquid phases generally make multiple counter current contacts, and the gas-liquid phases on each plate generally make cross flow. ② Packing tower, gas-liquid two-phase continuous countercurrent contact.

A typical distillation apparatus consists of a distillation tower body, condenser, reflux tank, and reboiler, among other equipment. The feed enters the distillation tower from a certain section of the tray, and this tray is called the feed plate. The feed plate divides the distillation tower into two sections: the upper and lower sections. The section above the feed plate is called the distillation section, while the section below the feed plate is called the distillation section.

operational evaluation

The main indicators of distillation operation are: ① purity of the product. The number of trays in a plate tower or the height of the packing layer in a packed tower, as well as the position and reflux ratio of the liquid feed, all have a certain impact on the purity of the product. Adjusting the reflux ratio is the main means used to control product purity in distillation tower operations. ② Component recovery rate. This is the ratio of component content in the product to component content in the feed solution. ③ Total operating cost. This mainly includes the heating cost of the reboiler, the cooling cost of the condenser, and the depreciation cost of the distillation equipment. Changing the reflux ratio during operation directly affects the first two expenses.

Application

Distillation towers have a wide range of applications in petrochemical production, often used to obtain high-purity products. It can help extract various fuels from crude oil, or separate high-purity products in chemical production, as well as obtain specific components from mixtures.