- Home

- >

- Products

- >

- Extraction

- Ultrasonic-assisted herbal Extraction Equipment

ultrasound assisted extraction equipment of soy isoflavones

ultrasound assisted extraction equipment of soy isoflavones

ultrasound assisted extraction equipment of soy isoflavones

Product Detail

Product Description

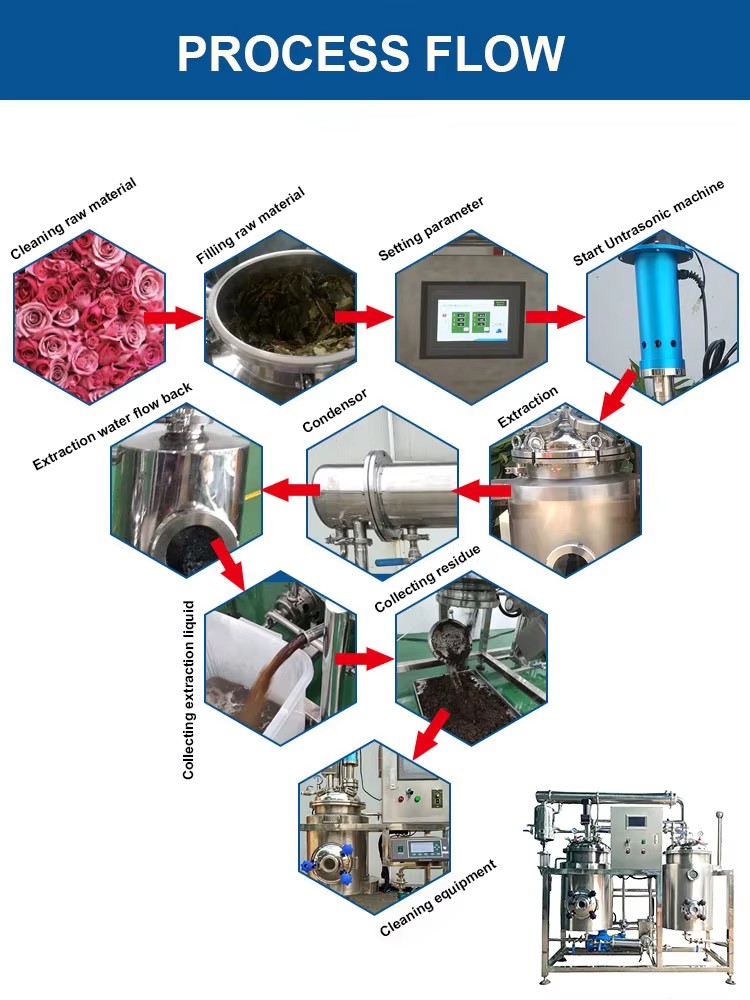

Soy isoflavones are a type of plant estrogen with multiple physiological activities, widely used in the fields of food and medicine. The traditional ethanol reflux method has problems such as long heating time and high impurities, ultrasound assisted extraction equipment of soy isoflavones technology has become the mainstream optimization method due to its unique physical effects (such as cavitation) that can effectively destroy plant cell walls and promote the dissolution of active ingredients.

This ultrasound assisted extraction equipment of soy isoflavones technology utilizes the high-frequency vibration and impact force generated by ultrasound in liquid to cause the cell structure of soybean meal or soybean powder to rupture, thereby accelerating the diffusion rate of isoflavones into the solvent. Research has shown that this method can not only improve extraction efficiency, but also operate at lower temperatures, which is beneficial for protecting thermosensitive components

Comparison of key process parameters

Different studies have optimized extraction conditions for different types of raw materials, such as soybean meal, black beans, and fermented soybean meal. The following is a summary of key parameters that combine multiple experimental results:

Ethanol concentration of 60% -80%, higher than 75% helps to improve the solubility of polar compounds; 60% of black beans are preferred

The ratio of material to liquid is 1:15 to 1:35 (g/mL), commonly 1:20 or 1:35; Too high affects concentration efficiency, too low leads to insufficient extraction

Extraction time is 20-50 minutes, significantly shorter than traditional heating for several hours; Ultrasound can reach its peak in 40-50 minutes

Extraction temperature of 40-60 ℃, temperature control is beneficial for protecting active ingredients; 60 ℃ is commonly used to enhance dissolution kinetics

Ultrasonic frequency 20-40 kHz, belonging to low-frequency ultrasound, strong penetration, suitable for solid material processing

Raw material pretreatment, crushing and sieving (20-40 mesh), degreasing treatment to increase contact area; Ether or n-hexane degreasing can reduce oil interference

Additional explanation: In practical processes, single factor experiments and orthogonal designs are often combined to determine the optimal combination. For example, when using defatted soybean meal, with 80% ethanol, a solid-liquid ratio of 1:20, and ultrasonic treatment at 60 ℃ for 30 minutes, the extraction rate can reach 0.3522%; For black beans, 60% ethanol, 50 ℃, 50 minutes, and passing through a 20 mesh sieve can achieve an extraction rate of 1.91%

Technical advantages and applicable scenarios

High efficiency: The cell has strong wall breaking ability, and the extraction rate is increased by nearly 4% compared to traditional methods.

Short time: shortened from several hours to several tens of minutes, significantly increasing production capacity.

Low energy consumption: No need for prolonged high-temperature heating, saving energy and reducing equipment losses.

Good activity retention: Low temperature operation avoids thermal degradation and maintains antioxidant and other biological activities.

Widely used: It has been widely applied in traditional Chinese medicine, health products, food industry and other fields

suggestion

If you are conducting laboratory optimization or pilot scale up, it is recommended to:

Firstly, crush and degrease the raw materials for pretreatment;

Using response surface methodology or orthogonal experimental system to optimize the four elements (ethanol concentration, time, temperature, and solid-liquid ratio);

Control the temperature between 50-60 ℃ to avoid component loss caused by excessive temperature;

Multiple extractions (such as two) can be considered to further improve the overall yield

XI'AN BIOLAND INSTRUMENT CO.,LTD -

We're known as one of the most professional herbal extraction machine ,ultrasonic herb assissted extraction machine,low temperature solvent extraction machine, Aromatic Plant Oil Extraction machine,Supercritical co2 extractor,Thermal reflux extraction equipment ,low temperature extraction and concentration equipment,

stainless steel ultrasonic reactor,electric heating mixing tanks,jacketed glass chemical reactor, ultrasonic homogenizer sonacitor,Chemical crystallization filtration reactor,Chemical distillation purification reactor,high shear homogenizer mixer,nutsche filter, low temperature drying equipment, cosmetic nano emulsion mixing equipment...

manufacturers in China. We warmly welcome you to buy cost-effective equipment for sale here from our factory. For more information, please contact us !!!

info@bioland-china.com/info@biolandlab.com