- Home

- >

- Products

- >

- Extraction

- Ultrasonic-assisted herbal Extraction Equipment

Stevia sugar Ultrasonic Extraction Machine

Stevia sugar Ultrasonic Extraction Machine -Herb Extraction and Concentration Equipment,stevia dry powder extraction machine

Customization:Available ultrasonic stevia sugar extraction machine ,Low Temperature vacuum Extraction Machine, Ultrasonic-assisted herbal Extraction Equipment

Product Detail

Product Description of stevia sugar extraction machine

What is ultrasonic extraction?

Some effect such as: high acceleration, emulsification, diffusion, crushing and stirring which produced by ultrasonic radiation pressure will increase the movement frequency and speed of matter molecules, so it will promote the extraction.

ultrasonic low-temperature stevia extraction equipment optimizes the product structure based on the original dynamic heat extraction unit to integrate the energy-concentration ultrasonic generator and solvent recovery equipment. In this equipment, the production process of ultrasonic extraction, filtration, solvent recovery, and essential oil condensation is completed in one step, which greatly saves raw materials and working time, and the working efficiency is increased by 60% to 80% compared with the general multifunctional extraction equipment.

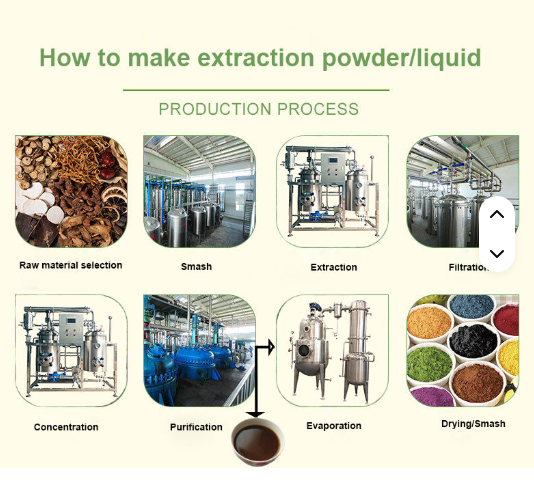

Stevia extract production line

Harvesting:The first step is to harvest the leaves of the Stevia rebaudiana plant. The leaves contain the steviol glycosides, which are responsible for the sweet taste.

Drying:After harvesting, the leaves are dried to reduce their moisture content.

Crushing or grinding: The dried leaves are crushed or ground into smaller particles, increasing the surface area for the extraction process.

Extraction:There are several methods for extracting steviol glycosides from the crushed leaves. Some common methods include:

Water extraction: The crushed leaves are mixed with hot water, and the steviol glycosides are leached into the water. This creates a stevia leaf extract.

Ethanol extraction: The crushed leaves are mixed with food-grade ethanol (alcohol) to extract the steviol glycosides.

Filtration:After the extraction process, the liquid extract undergoes filtration to remove any remaining plant material and impurities, leaving a more concentrated solution of steviol glycosides.

Purification:The concentrated extract may still contain other compounds alongside the steviol glycosides, so further purification is necessary.

Concentration: The purified steviol glycosides are then concentrated to increase their sweetness. This step reduces the volume of the final product, making it more efficient for storage and transportation.

Drying and crystallization: The concentrated extract is dried, and the steviol glycosides are crystallized to obtain a pure form of stevia sweetener.

Key Features of stevia sugar extraction machine

Stevia herbal extraction Equipment advantages:

1. This stevia herbal extraction machinery or stevia herbal plant extract machine has excellent manufacture,completecollocation,simple operation.It is consist of extracting tank,concentrated pot,storage tank for liquid material,condenser,oil-water separator, filter, delivery pump,vacuum pump and so on. We have steam heating and electric heating,the user can operate it only to engage the steam or electricty.

2.This ultrasonic stevia extraction equipment collect extraction,vacuum concentration,solvent recovery together and it can realize the operation of normal temperature extraction,low temperature extraction,hot circumfluence,low temperature circumfluence,low temperature concentration and essential oil collection etc.

3.The concentration proportion can get above to1.4 and the temperature can be controlled between 48-100°C freely,so it is espically suitable for some high heat-sensitivity material and some material is sensitive to high temperature.

4.This stevia ultrasonic extraction machine can configure with PLC control system according to user's demand and control the parameter during the processing to enhance the production efficiency and quality.

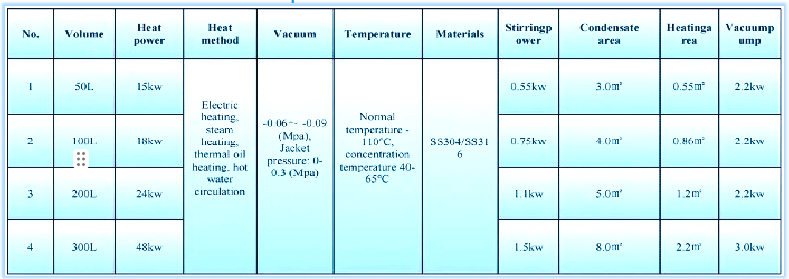

Technical description

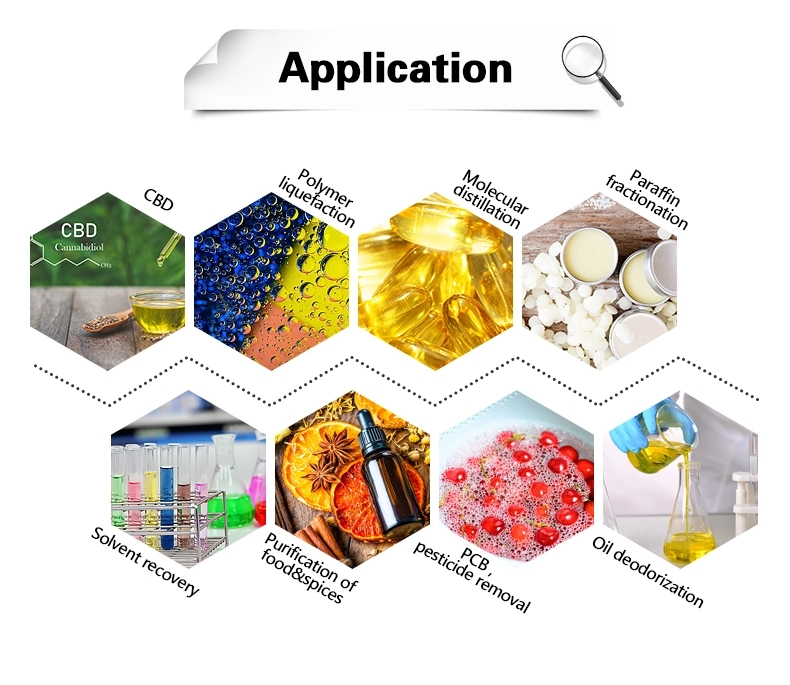

Appliance

Stevia, as a new type of sweetener, can be widely used in various food, beverage, pharmaceutical, and daily chemical industries. It can be said that almost all sugar products can use stevia to replace some sucrose or all synthetic sweeteners such as saccharin.