- Home

- >

- Products

- >

- Extraction

- Ultrasonic-assisted herbal Extraction Equipment

ultrasound assisted extraction of peppers

ultrasound assisted extraction of capsaicinoids from peppers

ultrasound assisted extraction of capsaicinoids from peppers

Product Detail

Product Description

Capsaicin or capsaicinoids is the main spicy component in chili peppers, with various physiological activities such as pain relief, anti-inflammatory effects, and promotion of fat metabolism.

Traditional extraction methods, such as ethanol reflux, suffer from high energy consumption and low efficiency. However, ultrasound assisted extraction or ultrasound assisted extraction of capsaicinoids from peppers technology utilizes cavitation effect to accelerate cell rupture and component dissolution, which has the advantages of high extraction efficiency, short time, and low energy consumption. It has been widely studied and applied.

This ultrasound assisted extraction of capsaicinoids from peppers technology destroys plant cell walls through mechanical vibration, cavitation, and thermal effects of ultrasound, allowing capsaicin to be released into the solvent faster, thereby improving extraction rates and shortening process cycles. Different studies optimize fresh or dried pepper raw materials using different solvent and parameter combinations

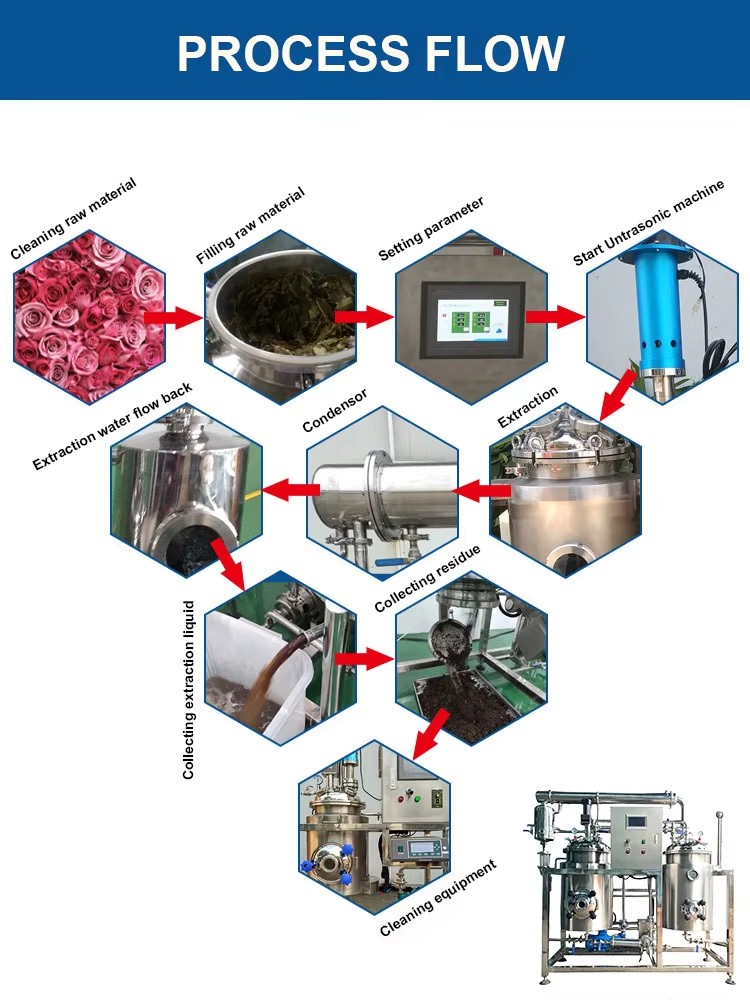

Process flow and key parameters of ultrasound assisted extraction of capsaicinoids from peppers

Raw material preparation

Select mature red chili peppers, wash them, remove the stems, dry them, crush and sieve them (usually 60-80 mesh).

Solvent selection

Common solvents include ethanol, methanol, acetone, tetrahydrofuran, and their mixtures. Ethanol is more suitable for food grade extraction due to its safety and environmental friendliness; Methanol: Tetrahydrofuran (1:1) has shown higher extraction efficiency in some studies.

Ultrasonic extraction process

Mix chili powder with solvent in proportion and place it in an ultrasonic device for ultrasonic treatment at a set temperature.

After extraction, filter and collect the filtrate; Some processes require repeated extraction 1-3 times to improve yield.

subsequent processing

The filtrate is distilled to recover the solvent and obtain a crude extract;

Further purification can be achieved through column chromatography to obtain high-purity capsaicin products

suggestion

If used for industrial production, it is recommended to combine response surface methodology or orthogonal experiments to optimize the process of local raw materials, with a focus on the four main influencing factors of material to liquid ratio, solvent concentration, ultrasound time, and temperature. Prioritize the use of edible grade ethanol as a solvent to ensure product safety and compliance

XI'AN BIOLAND INSTRUMENT CO.,LTD -

We're known as one of the most professional herbal extraction machine ,ultrasonic herb assissted extraction machine,low temperature solvent extraction machine, Aromatic Plant Oil Extraction machine,Supercritical co2 extractor,Thermal reflux extraction equipment ,low temperature extraction and concentration equipment,

stainless steel ultrasonic reactor,electric heating mixing tanks,jacketed glass chemical reactor, ultrasonic homogenizer sonacitor,Chemical crystallization filtration reactor,Chemical distillation purification reactor,high shear homogenizer mixer,nutsche filter, low temperature drying equipment, cosmetic nano emulsion mixing equipment...

manufacturers in China. We warmly welcome you to buy cost-effective equipment for sale here from our factory. For more information, please contact us !!!

info@bioland-china.com/info@biolandlab.com