- Home

- >

- Products

- >

- Extraction

- Multi-functional Extraction and Concentration Equipment

hot water Reflux Herbal Solvent Extraction Machine

Hot water Reflux Hydro Distillation Units Herbal Oils Solvent Extraction Machine

Heat hot water Reflex Chinese Herbal Plant Stean Root Solvent Concentration and Extraction Machine

Product Detail

Product Description

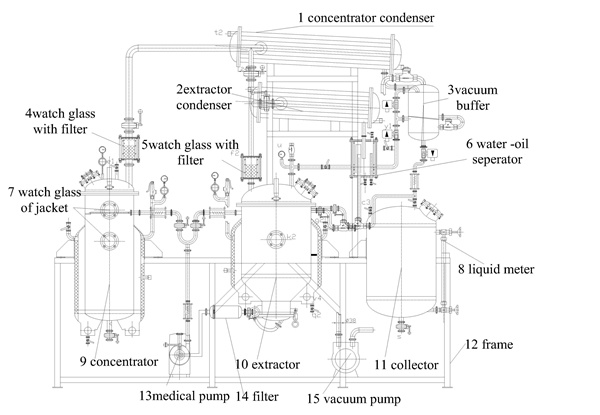

The components of Hot water Reflux Herbal Extraction Machine can be divided into extraction tank, condenser,cooler, separator, filter, pneumatic control system of slag gate, etc. It can be designed and manufactured according to different equirements of users.

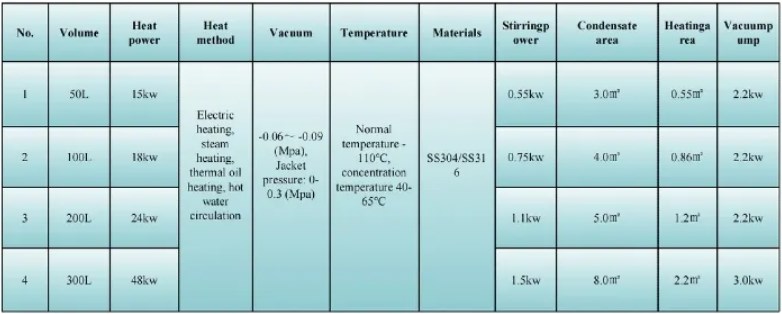

Multifunctional herbal hot water Thermal Reflux Soxhlet Extraction And Concentrator Machine Technology data Specification:

Electrical heating multifunctionl poilt plant extraction and concentrator machine,as the extractor medium difference ,it can be devided as below production process:

1). For water extraction: water and herbal raw material are put into the extraction tank and began to use electricity to heat the water to provide a heat source. After the tank boils, reduce the supply heat source and keep the boiling in the tank. The maintenance time depends on the extraction pharmacological process. For example, cooling water is needed for closed extraction to cool the steam and return to the extraction tank to maintain the circulation and temperature.

2). For solvent extraction: firstly, the herbal and solventmust be sealed in the tank, and the heat source steam shall be supplied to the interlayer. Open the cooling water to reduce the supply heat source when the tank reaches the required temperature, so that the rising vapor alcohol can flow back into liquid alcohol after passing through the condenser. In order to improve the efficiency, the pump can be used to force the circulation, so that the medicine liquid can be sucked out from the lower part of the tank through the pump, and then the upper part of the cylinder is imported back into the tank, and the local ditch can be removed Flow.

3). For Oil extraction : first add the Chinese herbal and water containing the volatile oil into the extraction tank, open the

circulation valve of the oil separator, adjust the bypass return valve, open the supply heat source valve to reach the volatile

temperature, open the cooling water for cooling, keep a certain height in the separator to separate the cooled liquid medicine,

and then rotate the oil-water separator.