- Home

- >

- Products

- >

- Extraction

- Multi-functional Extraction and Concentration Equipment

Herbal Extract Vacuum Concentrator

Herbal Extract Vacuum Concentrator -Static vacuum Chinese medicine extraction machine

Herbal Extract Vacuum Concentrator

Product Detail

Product Details

Xi'an Bioland Instrument Equipment Co., Ltd. is a major manufacturer of herbal extraction equipment, with multiple professional manufacturers of various extraction machines covering various technical routes such as ultrasonic, static vacuum, Soxhlet, hot reflux, centrifugation, supercritical extraction, etc

Herbal Extraction Machine or Herbal Extract Vacuum Concentrator is used to separate active ingredients from plants and is widely used in the traditional Chinese medicine, health products, cosmetics, and food industries. With the increasing demand for natural products, the market for such equipment continues to expand, forming a mature industrial chain that provides complete solutions from laboratory scale to industrial production lines

Working principle of static vacuum extraction machine or Herbal Extract Vacuum Concentrator

The working principle of the Herbal Extract Vacuum Concentrator is mainly based on vacuum low-temperature extraction and solvent reflux extraction.

The specific steps are as follows:

1)Herbal Extract Vacuum Concentrator Put the medicinal herbs to be extracted into the extraction tank, and add a certain proportion of solvents such as water, ethanol, methanol, acetone, etc. according to the production process (add according to the process).

2)Herbal Extract Vacuum Concentrator Extract the raw material, and the extraction temperature can be set according to actual needs. During the extraction process, vacuum negative pressure is used for low-temperature extraction, controlling the working temperature inside the extraction tank at 60-80 ℃ to prevent the effective components of traditional Chinese medicine from evaporating and losing.

3)After the extraction is completed, open the pipeline valves in order and draw the liquid into the concentration tank for concentration. The temperature of the concentrated solution is set at the desired value, and the vacuum degree is maintained at -0.05 to -0.09MPA. The secondary steam generated during concentration is converted into condensate through the condenser and cooler, and refluxed to the extraction tank as a new solvent to be added to the medicine. The new solvent passes through the medicinal layer from top to bottom and reaches the bottom of the extraction tank. The soluble components in the medicine dissolve in the solvent in the extraction tank, forming a new solvent reflux extraction until completely dissolved (the extraction liquid is colorless).

4)Herbal Extract Vacuum Concentrator of The extraction tank is equipped with two-stage stirring to ensure that the larger volume of materials come into full contact with the solvent, accelerating the precipitation of effective ingredients. The equipment has a high degree of automation control, and is easy to operate with accurate and reliable data collection.

In addition, during the use of the hot reflux extraction and concentration unit, the extraction equipment and concentration equipment can operate independently or in conjunction, improving the rationality of equipment operation and making operation convenient and easy. The alcohol recovery capacity is large, and the vacuum concentration process is adopted, which increases productivity by 5-10 times compared to similar old equipment, reduces energy consumption by 30%, and has the characteristics of low investment and high recovery efficiency.

In summary, the static vacuum herbal extraction machine or Herbal Extract Vacuum Concentrator effectively maintains the active ingredients of traditional Chinese medicine through vacuum low-temperature extraction and solvent reflux extraction, improving extraction efficiency and purity.

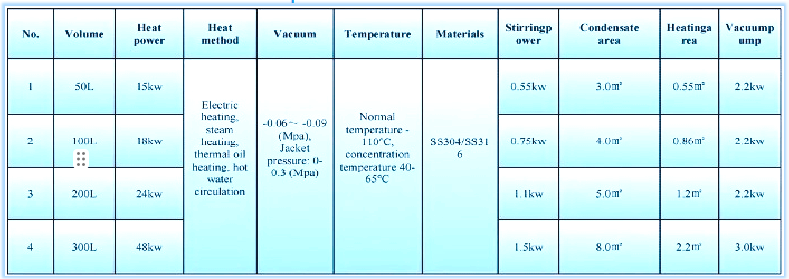

Technical Specifications

Static vacuum extraction or Herbal Extract Vacuum Concentrator is a traditional Chinese medicine extraction process carried out under negative pressure conditions. It achieves low-temperature extraction by reducing the boiling point, effectively protecting thermosensitive components and improving extraction efficiency and product stability. Low temperature protection of active ingredients: the boiling point of water decreases under vacuum conditions, and extraction can be completed at 60-80 ℃, avoiding high temperature damage to thermosensitive substances such as flavonoids and saponins