- Home

- >

- Products

- >

- Extraction

- Multi-functional Extraction and Concentration Equipment

rosemary extraction and concentration equipment

rosemary extraction and concentration equipment

rosemary extraction and concentration equipment

Product Detail

Introduction

Rosmarinus officinalis or Rosemary is a plant rich in antioxidants, with its main active substances including oxalic acid, rosmarinic acid, salvianolic acid, and ursolic acid. These ingredients have strong antioxidant properties and are widely used in fields such as food, medicine, cosmetics, etc.

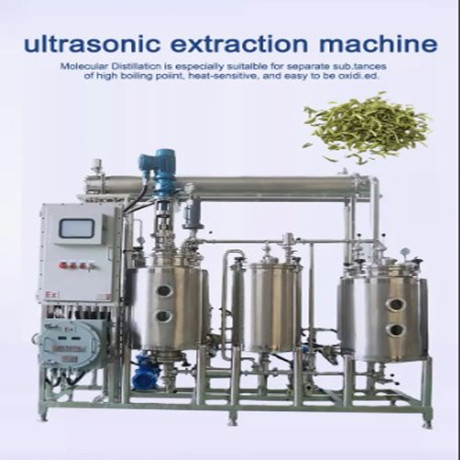

Rosemary Solvent extraction and concentration equipment is a multifunctional unit that integrates extraction, concentration, and oil-water separation. It is widely used in the production of plant essential oils, hydrosols, and extracts, and supports various processes such as steam distillation and hot reflux. It meets GMP standards and is suitable for scientific research, pilot testing, and industrial production

Therefore, how to efficiently and safely extract these active ingredients has become a key focus in industrial production.?

Core components and functional modules

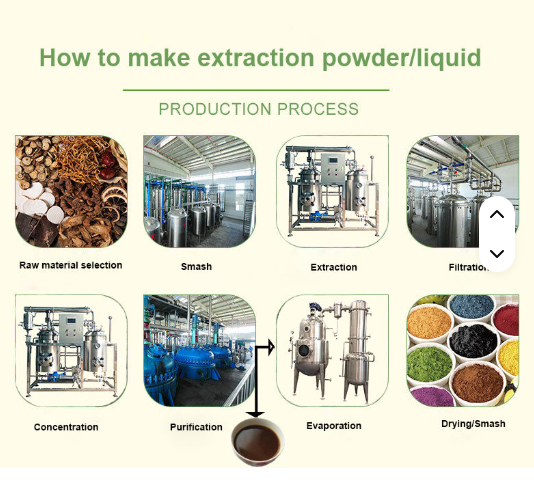

A complete set of rosemary extraction and concentration equipment typically includes the following components:

Extraction tank: used for soaking and distillation of raw materials, mostly made of SUS304 stainless steel, supporting normal/negative pressure operation.

Condenser: Tube or coil design, quickly cools steam and improves recovery rate.

Oil water separator: Made of transparent glass or stainless steel structure, it is easy to observe the layering of essential oils and achieve automatic separation.

Concentration system: single effect, double effect or MVR concentration, can be concentrated under low temperature and reduced pressure to protect thermosensitive components.

Control system: PLC+touch screen control, supporting online monitoring of temperature, pressure, and liquid level

the Extraction processing of Rosemary Solvent extraction and concentration equipment

1)Ethanol concentration of 70% -95% (v/v), high concentration (such as 95%) is more conducive to the extraction of fat soluble antioxidants; Lower concentrations (such as 70% -80%) can be used for specific target substances such as rosmarinic acid.

2)Material to liquid ratio: 1:5 to 1:12 (g/mL), which means adding 5-12mL of solvent per gram of raw material. 1: 5 is a common optimization value. If it is too high, the solvent will be wasted, and if it is too low, the extraction will be insufficient. The recommended ratio for microwave method is 1:12.

3)Extraction methods: reflux extraction, ultrasound assisted, microwave assisted, reflux is the most classic; Ultrasound and microwave can significantly shorten time and improve efficiency. Microwave assisted technology can achieve high yields in just 5 minutes.

4)Extraction time :Extract 2-3 times, multiple extractions can improve the overall yield, and the increment is generally limited after 2-3 times.

5)Temperature and time: 60-75 ℃, 1-3 hours each time. Temperature affects solubility and stability; Excessive time may lead to degradation of 20. The microwave method can be completed within 5 minutes.

suggestion

The rosemary extraction and concentration equipment has developed into a multifunctional, automated, and GMP compliant integrated system that supports the full range of needs from laboratory trials to industrial production. When choosing, it should be comprehensively judged based on factors such as the purpose (essential oil/hydrosol/extract), production capacity, budget, and whether solvent recovery is needed. At present, steam distillation and condensation separation are the mainstream in the market, and membrane concentration can further improve quality and energy efficiency

If pursuing high purity and low residue products, macroporous adsorption resin purification or membrane distillation technology can be introduced on the basis of ethanol extraction for further refinement. For small-scale rapid extraction in the laboratory, it is recommended to use microwave-assisted ethanol extraction method (80% ethanol, 1:12 solid-liquid ratio, 700W power, 5 minutes), which has high efficiency and stable yield

XI'AN BIOLAND INSTRUMENT CO.,LTD -

We're known as one of the most professional herbal extraction machine ,ultrasonic herb assissted extraction machine,low temperature solvent extraction machine, Aromatic Plant Oil Extraction machine,Supercritical co2 extractor,Thermal reflux extraction equipment ,low temperature extraction and concentration equipment,

stainless steel ultrasonic reactor,electric heating mixing tanks,jacketed glass chemical reactor, ultrasonic homogenizer sonacitor,Chemical crystallization filtration reactor,Chemical distillation purification reactor,high shear homogenizer mixer,nutsche filter, low temperature drying equipment, cosmetic nano emulsion mixing equipment...

manufacturers in China. We warmly welcome you to buy cost-effective equipment for sale here from our factory. For more information, please contact us !!!

info@bioland-china.com/info@biolandlab.com