50L chemical distillation column reactor for strong acid alkali

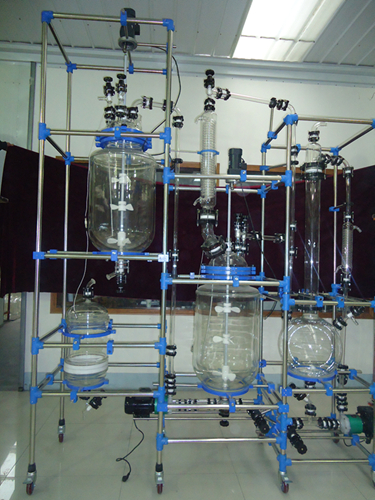

Industrial Pilot Plant Distillation Column 50L Jacketed Glass Reactor

Distillation and Rectification System Double-Deck Glass Distillation Column Reactor 50L 100L 200L

Product Detail

Product Description

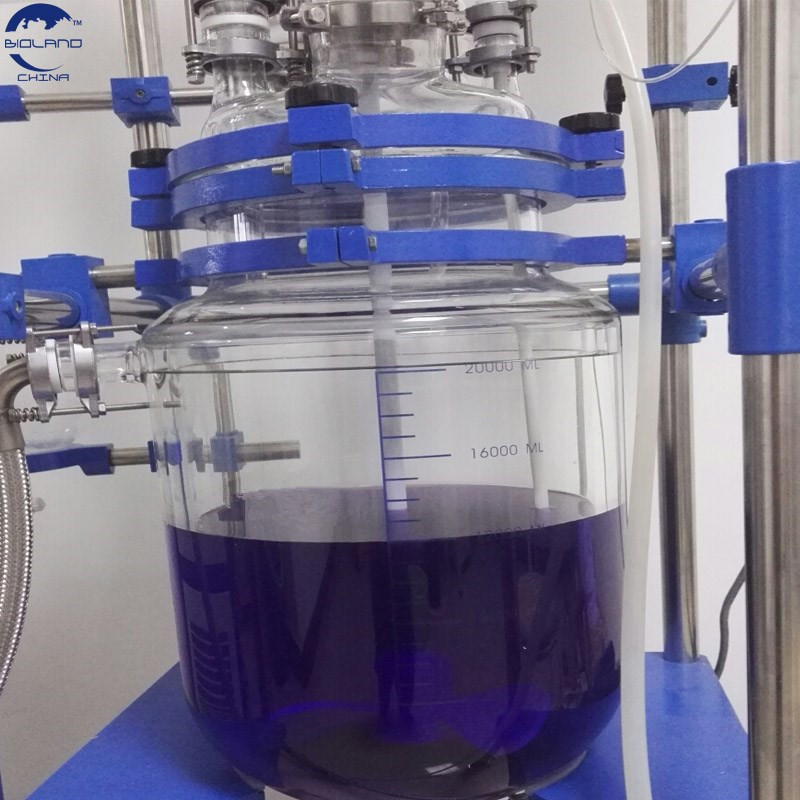

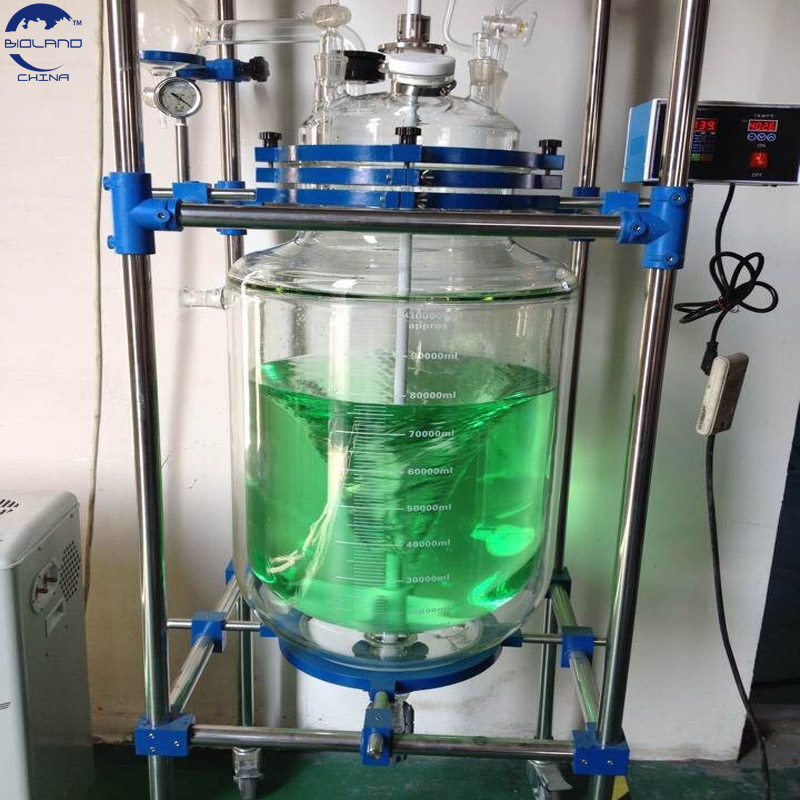

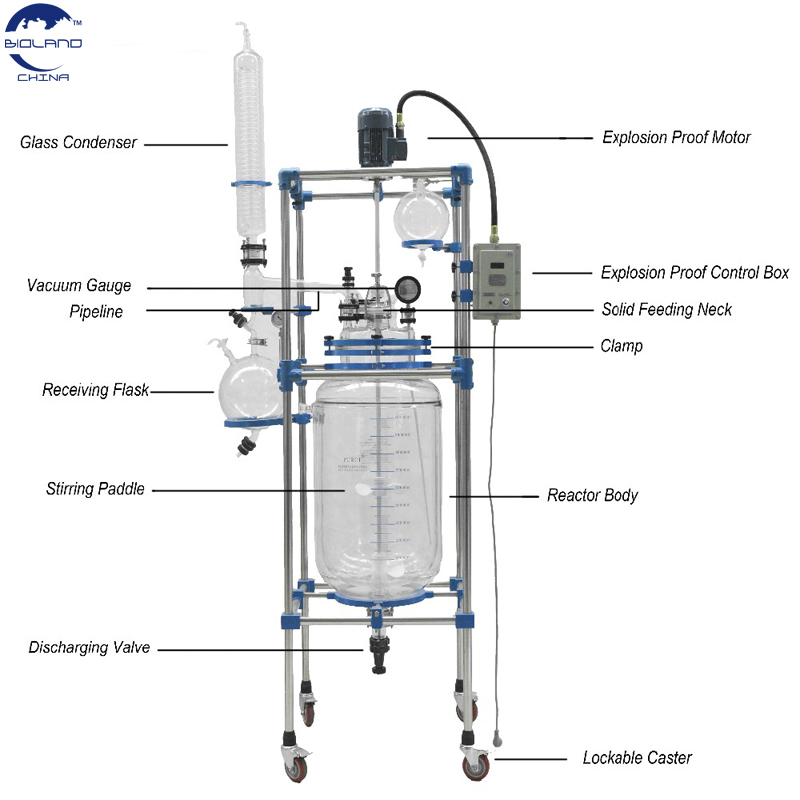

The double-layer glass reactor is a double-layer glass design. The inner layer of the double-layer glass reactor / double-layer glass reactor is placed in the reaction solvent to make the stirring reaction. The interlayer can pass different cold and heat sources (frozen liquid, hot water or heat Oil) to do the heating or cooling reaction. In the set constant temperature conditions, in the closed glass reactor, according to the use of requirements under normal pressure or negative pressure conditions for stirring reaction, and can do the reaction solution reflux and distillation, is a modern fine chemical plant, bio-pharmaceutical and New material synthesis of the ideal pilot, production equipment.

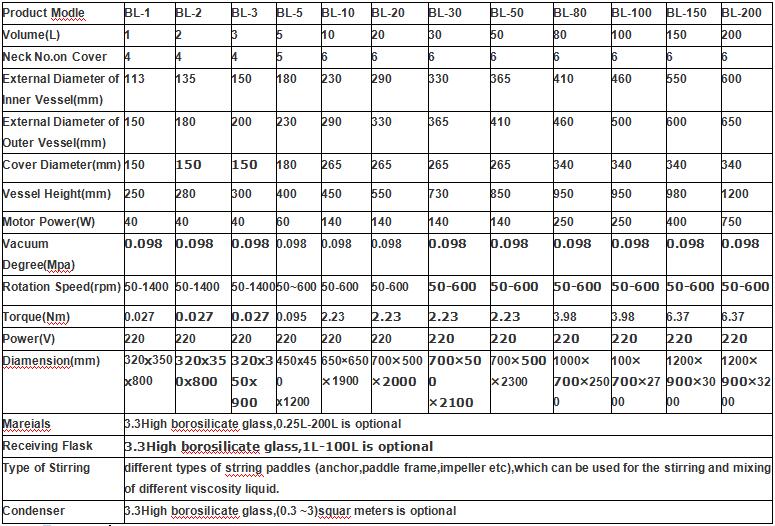

Product Parameters

Our Advantages

1. GG17 (3.3) borosilicate glass, with good chemical and physical properties.

2. The evaporation and back-flow of reaction material can be controlled.

3. Reacting Temperature: -120~300ºC

4. The design of a large bottle mouth, easier to clean.

5. It can be used as a distillation synthesis device.

6. The sealing performance is 0.098 Mpa.

7. LCD display, easier and more convenient to measure temperature.

8. Single layer or double layer PTFE Stirring leaf, corrosion resistance

Double-layer glass reactor can do a stirring reaction in the inner layer under the condition of vacuum. The interlayer can make constant temperature for heating or cooling reactions through the heat or cold source (freezing liquid, water, or hot oil). It is widely used in modern refined chemical, biological pharmacy, new material synthesis industry research experiments,etc. OEM is also welcomed.