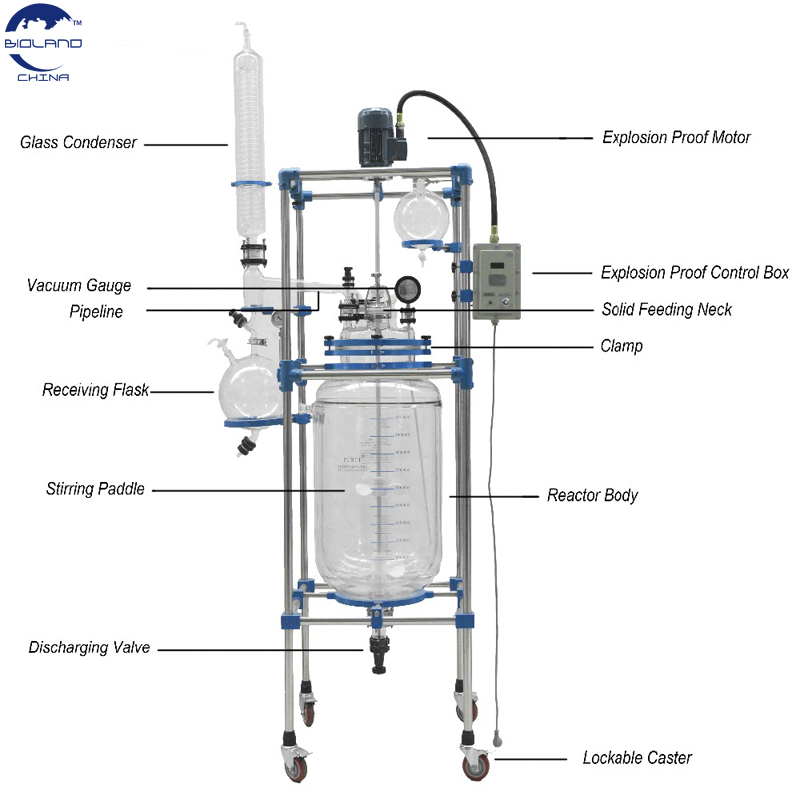

Hydrogenation Chemical batch Reactor for Chemical Synthesis

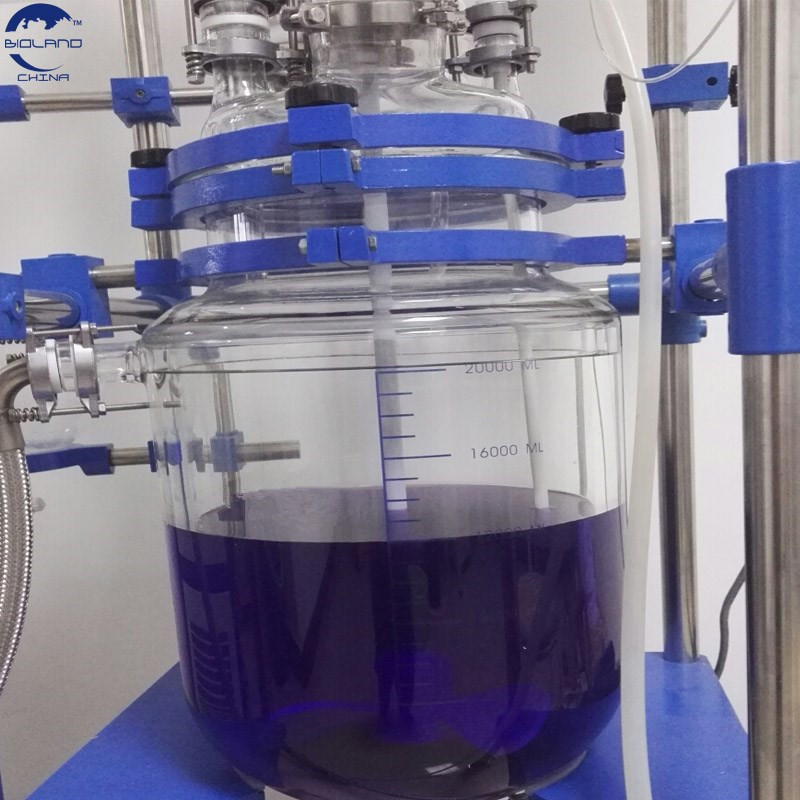

High Borosilicate Glass Reaction Kettle 1L to 200L for Chemical Synthesis

Small Capacity Anti-Explosion Lab Chemical Reactor Electric Heating Reaction Kettle

Product Detail

Product Description

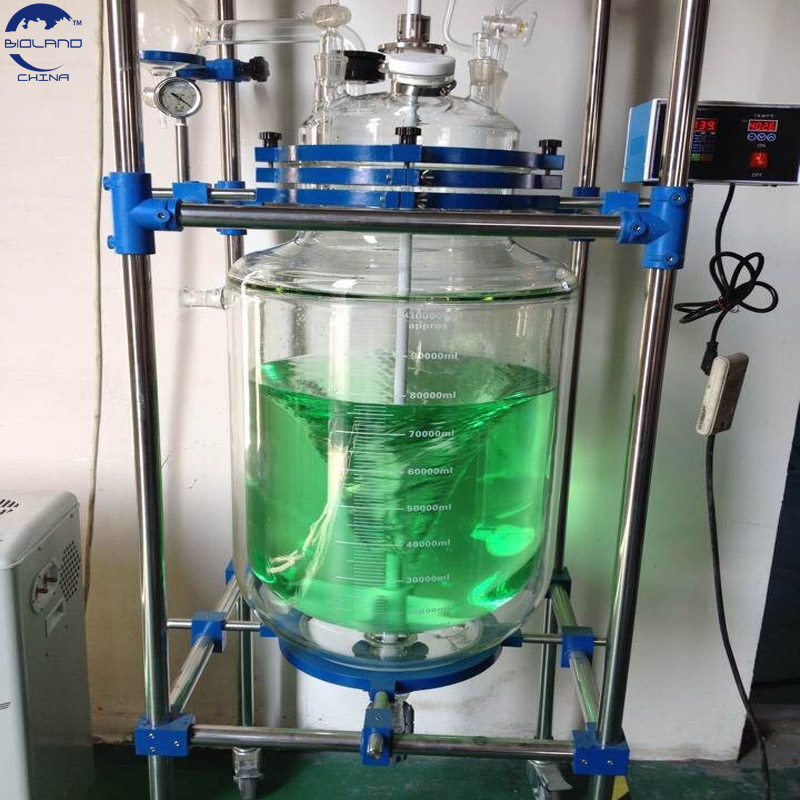

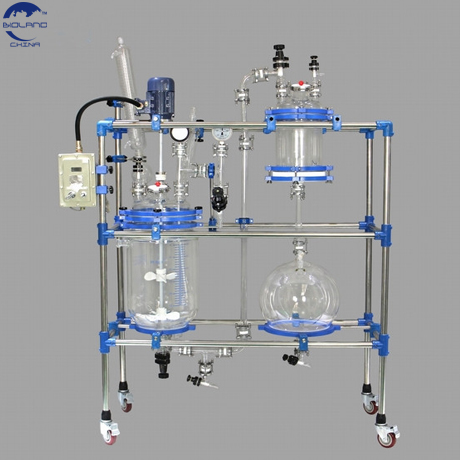

The Hydrogenation Chemical batch Reaction Kettle can be designed to be single, double or triple wall glass reactor.The reaction menstruum can be put into the inner layer to do stirring, interlayer can be connected with cold and heat source ( frozen liquid, hot water or hot oil) to do circulating heating or cooling reaction.

Hydrogenation Chemical batch Reaction Kettle is an ideal production equipment for the modern fine chemical, pharmaceutical and biological synthesis of new materials.

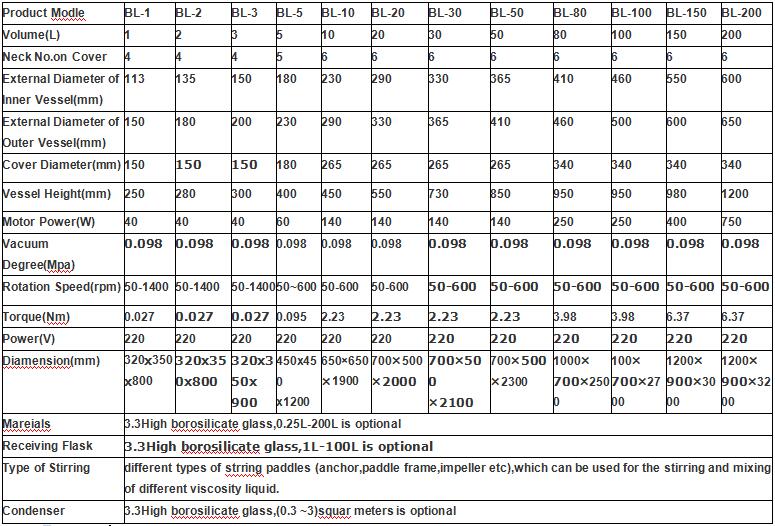

Product Parameters

Feature

Maximum working temperature is 200ºC, the minimum working temperature is -100ºC. And the maximum temperature difference between the internal and external of the reactor is 80ºC. When heating and cooling the reactor, it is recommended to monitor the temperature inside and outside the vessel continuously and heat up or cool down gradually to avoid accidents.

PTFE Hose: using temperature range -100ºC~150ºC(Optional)

Stirring Sealing(National Patent): excellent sealing, durable and corrosion resistant, long service life

Stainless Steel Thermal Insulation Hose: using temperature range -150ºC~300ºC, can be used for both high and low temperature circulating fluid pipeline

Ceramic Bearing: Abrasion resistant, corrosion resistant, long service life

Quick Connectors for Circulating Hose: It is easy to moving and disassembling.

PTFE Stirrer: Stirring shaft is PTFE rainforced stainless steel, strong and durable.

Hose manifold has two important functions:

Supporting the hose connected to the kettle body, thus reducing the pressure of the glass circulation joint, and the quick cycle joint is easy to assemble and disassemble.

It is convenient to replace the kettle body and discharge the heat transfer oil from the jacket to other containers cleanly and effectively.

Applications:

Hydrogenation Chemical batch Reaction Kettle are mainly used for synthetic reaction, distillation and concentration of different types of materials. We have single wall, double wall and triple wall glass reactors. The reactor can be pumped to a negative pressure state according to some experimental requirements. A constant pressure funnel or an adjusting valve on the feeding bottle allows you to add material to the vessel at a uniform and controlled speed. Condenser helps to recover some materials distilled during reaction. Circulating liquid can be filled into the jacket to heat or cool materials inside. Triple wall glass reactor with two jackets, the inner jacket is for circulating liquid, and the outer layer should be pumped to vacuum condition for thermal insulation.