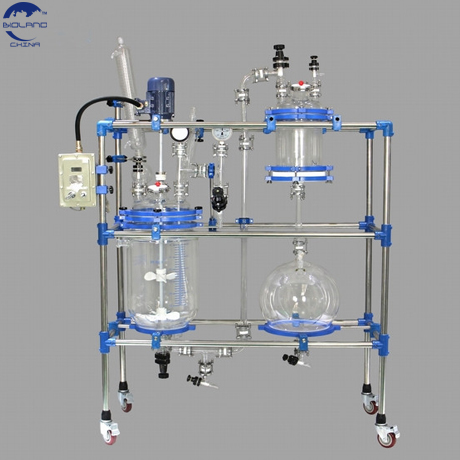

50L Nutsche Filter Reactor

Nutsche Filter Reactor-Laboratory Glass Nutsche Filter,filter reactor, vacuum jacketed reactor

Nutsche Filter Reactor,vacuum jacketed reactor ,Glass Nutsche Filter

Product Detail

1 The Nutsche Filter Reactor device is mainly used for solid phase synthesis operation, is an instrument type active sand core glass reactor, suitable for a variety of organic synthesis reactions such as polypeptides.

2 Glass parts are all using GG-17, the grinding hole at the interface is treated evenly, imported carbon fiber synthetic sealing material allows the vacuum level in the boiler to reach -0.098Mpa, which can meet the requirements of online distillation.

3 The top of the reactor has a feed port, which can be used for negative pressure feeding. The discharge material is tetrafluoro triple discharge, can be nitrogen protection in the boiler body

4 Imported IKA electric mixer without electric brush, no spark, can work continuously. No pollution glass mixing rod. Stainless steel 304 Teflon spray-coated anti-corrosion bracket.

The special design of the filter plate on the bottom of the boiler allows the equipment to withstand the pressure of up to 100 kg of reaction liquid and avoid the appearance of dead bodies on the bottom of the boiler.

5 Boiler body for double layer of glass sintered, between the two layers can pass coolant and heating liquid, unique gas-line injection into the liquid way to make the heat conduction faster and uniform.

6 The filter device is the first in the country, using flange and medical grade tetrafluoro material to be connected to the boiler body, the filter screen is imported ultra-polymer polyethylene material

1.High borosilicon glass furnace cover,the bushing can be customized opening to meet customers' different use habits and needs.

Equipped with a positive and negative pressure vacuum meter, it can monitor the vacuum level in real time so that the personnel can make corresponding operating adjustments.

2. Jacket all-inclusive boiler body

Boiler body jacket part of a package to the bottom, so that the bottom material is heated more evenly, the filter bottom plate area is increased, the reaction efficiency is improved.

3. Collect bottles

The reactor and the collector bottle are fixed in the same frame, allowing the user to complete the various operations of the reaction process and the material collection process in a relatively concentrated area

4. The filter device is domestic, using flange and medical grade tetrafluoro material made to be connected to the boiler body, the filter screen is imported ultra-polymer polyethylene material, easy to remove cleaning replacement

Application of Nutsche Filter Reactor:

Double-layer glass design, the inner layer into the reaction solvent can do the stirring reaction, the intermediate layer can pass on different cold heat sources (frozen liquid, hot water or hot oil) to do the circulating heating or cooling reaction. Under the setting of constant temperature conditions, in a closed glass reactor, it can be stirred under normal or negative pressure conditions according to the requirements of use, and can do the reaction solution reflux and distillation, is the ideal test and production facility for modern refinery, biopharmaceutical and new material synthesis