Lab Solid Phase Filter Crystal Reactor for Peptide synthesis

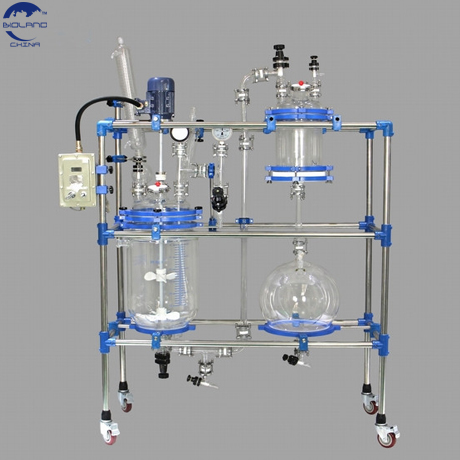

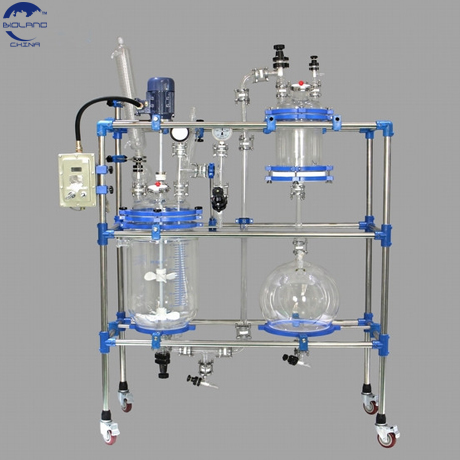

Solid Phase Crystal Filter Reactor-10-100L Peptide synthesis solid-phase crystallization reactor

Laboratory lithium battery reaction kettle, PH online detection control glass reactor kettle

Product Detail

Product Description

The Solid Phase Crystallization Filter Crystal Reactor for Peptide synthesis adopts High borosilicate glass or customize stainless steel kettle cover and kettle body, which are electrolytically polished and connected by flanges, which is convenient for disassembly, cleaning and replacement. The reactor is equipped with replaceable tetrafluoroethylene filter plates, which can be used for stirring, filtration, suction filtration, peptide synthesis, crystallization, pyrolysis and other processes. the glass solid phase reactor, it has a wider application range and can be operated under positive pressure conditions.

Feature

Solid Phase Crystallization Filter Crystal Reactor can be optionally customized for dispersion, mixing, emulsification, homogenization, and dissolution. The entire reaction process of stirring, homogenization, emulsification, dispersion, mixing, etc. of materials can be observed through glass under vacuum or pressure conditions.

It can simultaneously measure the temperature, pressure, viscosity, pH, and other properties of materials. Materials can also be heated or cooled.

1) The homogenizer emulsifying device of this machine can directly reach the bottom of the kettle and can use the internal circulation of the emulsifying head for emulsification. By using a high-speed emulsification device combined with slow scraping, the raw materials will form a strong circulating floc flow without any corners. The product can be fully mixed, emulsified, dispersed, and homogenized, forming a good and uniform molecular structure. This type of emulsification system has better emulsification effect than traditional ones.

2) The sandwich structure can directly perform heating and cooling functions, with a spiral guide plate inside for more thorough cooling of the material during cooling.

3) Rotary vane vacuum pump is used for raw material suction, saving manpower. Adopting vacuum suction, especially for powder materials, to avoid dust flying. The entire process is carried out under vacuum conditions to prevent the formation of bubbles in the material after high-speed mixing, which meets the requirements of hygiene and sterility. It can also be used to remove bubbles, making the product structure more compact and glossy, and achieving a longer shelf life. Water sealed pumps do not produce oil or gas and are suitable for GMP factory standards.

4) Scrapers can be disassembled and assembled without tools, and cleaning and maintenance work can be carried out.

5) The pot lid device is equipped with waterproof and dustproof floodlights and mirrors, making it easy to observe the production situation.

6) This machine has safety protection devices, such as vacuum safety devices, three-phase power safety devices, interlayer pressure safety valves, emergency stop buttons, etc., to ensure safe operation.

7) This unit is manufactured in accordance with GMP requirements and is currently one of the washing and maintenance production equipment in China.

Applicable industry scope

Food: aloe, pineapple, fruit tea, sesame, ice cream, moon cake filling, cream, jam, fruit juice, soybeans, bean paste, bean paste, peanut milk, protein milk, soymilk, dairy products, malt cream, essence, various drinks, etc.

Chemistry: paints, pigments, dyes, coatings, lubricants, greases, diesel, petroleum catalysts, emulsified asphalt, adhesives, detergents, plastics, fiberglass, leather.

Daily use: toothpaste, detergent, shampoo, shoe polish, cosmetics, shower gel, soap, shampoo, etc.

Medicine: various types of syrup, nutrient solution, ointment like medicine, biological products, pollen, royal jelly, various ointments

Architecture: Various coatings. Including interior and exterior wall coatings, anti-corrosion and waterproof coatings, cold porcelain coatings, colorful coatings, ceramic glazes, etc.

Paper making: pulp, adhesives, rosin emulsion, papermaking additives, resin emulsion, etc.

Pesticides: fungicides, seed coating agents, herbicides, pesticide emulsions, fertilizers, biochemical pesticides, biopesticides, etc

Other fields include textile industry, coal flotation agents, rare earths, dispersion and depolymerization of nanomaterials, and reactive extraction.