- Home

- >

- Products

- >

- Extraction

- Multi-functional Extraction and Concentration Equipment

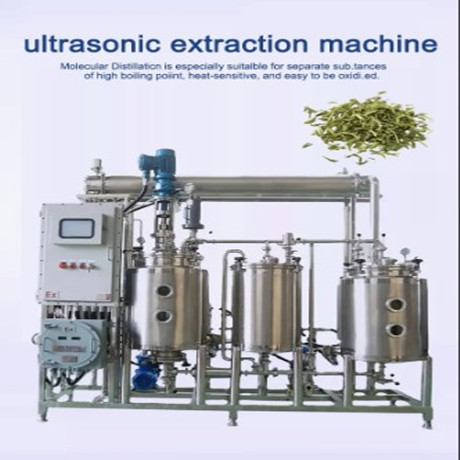

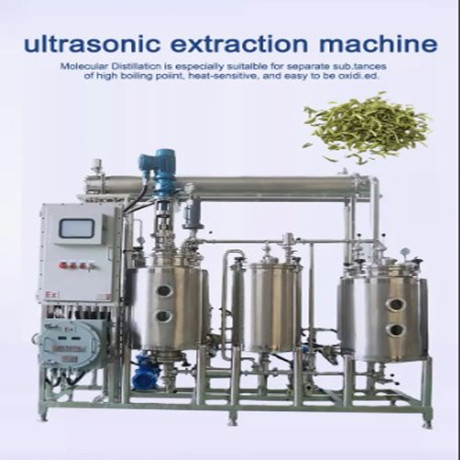

China Multi Functional 100L Ultrasonic Herb Extraction Machine

Herbal Extraction Equipment/Ultrasonic Extraction and Concentrate Machine

China Herbal Extraction Equipment / Ultrasonic Solvent Extraction and Concentrate Machine

Product Detail

Product Description

Herb extraction refers to the product formed by taking plants as raw materials and obtaining or concentrating one or more components in plants through physicochemical extraction and separation process according to the needs of the use of the final product, without changing the structure of its active components; According to needs, it can also be supplemented with excipients to make a powder or particle with good fluidity and humidity resistance, and there are also a small amount of liquid or oil form products. At present, the commonly used extraction methods are solvent extraction, ultrasonic extraction, microwave extraction and enzyme extraction, and supercritical fluid extraction and microwave-assisted extraction are widely used as new extraction technologies.

This Ultrasonic Herb Extraction Machine is a combined application device for the extraction and concentration of plant active ingredients. Its advantage

is that it integrates extraction and concentration, and adopts a fully enclosed continuous cycle extraction and concentration.

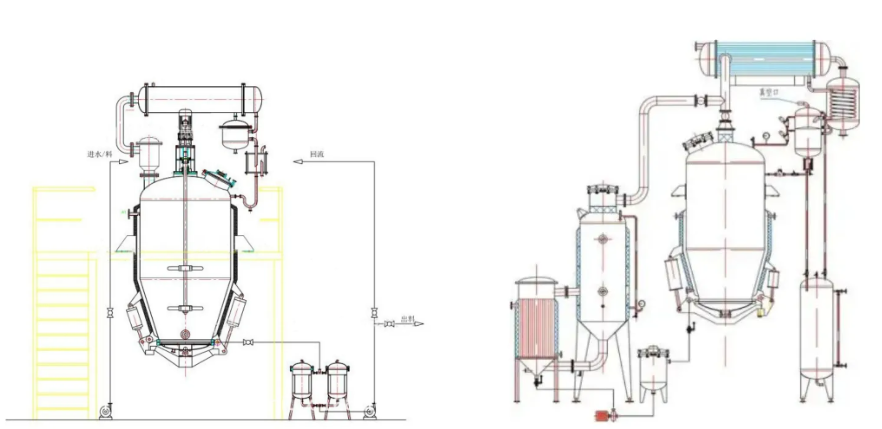

During the hot extraction process, the liquid in the extraction tank is connected to the heater and evaporator through a filter layer,

and undergoes cyclic concentration. The secondary steam generated by extraction and concentration is condensed by the

condenser, and the hot condensate flows back to the deep layer of the material in the extraction tank, allowing the material to

fully contact with the dynamic extraction and solvent supplementation, while shortening the extraction and concentration time

and greatly improving production efficiency.

Traditional Chinese medicine hot backset current low temperature draw low temperature concentrate unit comprehensive backset current, ooze and filter drawing, adverse current and hot backset current extraction and concentrate four kinds of principles. abstraction, concentrate two processes go on at the same time, one finish traditional medicine draw, concentrate the new craft of traditional Chinese medicine, take to change the draw pot keep high temperature with atmosphere fry the craft of boiling, utilize vacuum to shoulder proceed low temperature draw and low temperature concentrate, make working temperature to draw pot control in 60-80°C, concentrate temperature control in 50-70°C, guarantee crude drugs effective composition the distillation loss. Meanwhile draw and concentrate produced two steam enter backset current condenser become hot condensation liquid, falling back to and drawing it the pots, add to the crude drugs as the new solvent, the new solvent is passed the crude drugs layer from top to bottom, having played a oozing and filtering dynamically role, the soluble material which dissolves the crude drugs reaches the draw pot bottom, enter the concentrating device to concentrate again. According to practical experience and study for many years, hot condensation liquid of backset current invite within 2.5-3 hours drawing former solvent of pot all change once, can keep a higher density to the draw pot crude drugs in unit time.